2026 Top Trends in Exterior Sheathing for Sustainable Building

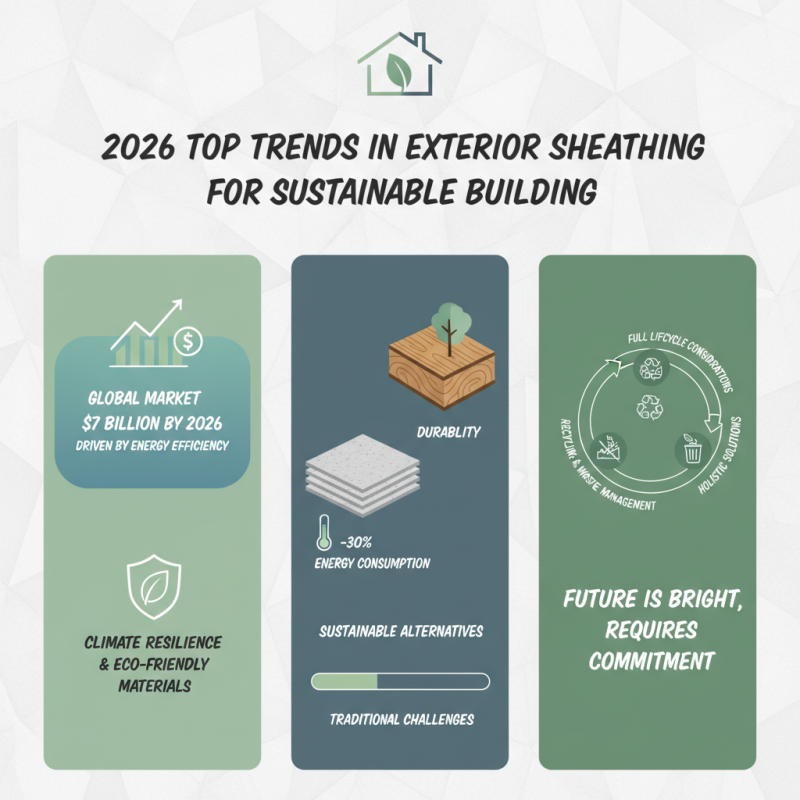

As sustainable building practices evolve, the role of exterior sheathing becomes increasingly crucial. Recent industry reports indicate that the global exterior sheathing market is projected to reach $7 billion by 2026, driven by the demand for energy-efficient buildings. With climate resilience becoming a priority, the shift towards eco-friendly materials in exterior sheathing is evident.

Architects and builders are exploring innovative options, such as fiber cement and engineered wood. These materials not only enhance durability but also reduce environmental impact. For instance, studies show that fiber cement can provide exceptional insulation, leading to a 30% reduction in energy consumption. However, challenges remain. Many traditional sheathing products still dominate the market, raising questions about adoption rates for sustainable alternatives.

Additionally, sustainability must consider the full lifecycle of materials. While new technologies emerge, issues like recycling and waste management need attention. This is essential for ensuring a truly sustainable approach. The future of exterior sheathing is bright, yet it requires ongoing scrutiny and commitment to holistic solutions.

Innovative Materials in Exterior Sheathing for Eco-Friendly Constructions

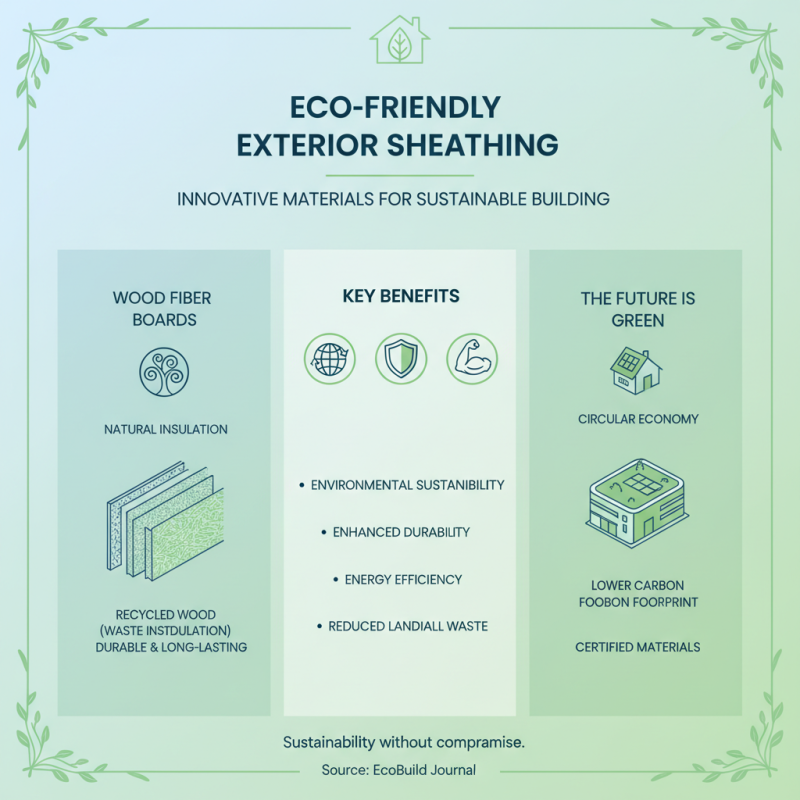

Innovative materials are transforming exterior sheathing for eco-friendly constructions. These materials emphasize sustainability without compromising durability. For example, wood fiber boards are gaining popularity due to their natural insulation properties. They are made from recycled wood, which helps reduce waste in landfills. Their lightweight nature also allows for easier installation.

Another noteworthy option is the use of magnesium oxide boards. These boards are fire-resistant and have excellent moisture control. They can help maintain a stable indoor climate, reducing energy costs. Yet, the production process still raises questions about environmental impacts. Are we fully aware of the carbon footprint involved?

Recycled content in sheathing materials is crucial. Some companies are exploring the use of post-consumer plastics and other waste products. This innovation reduces reliance on virgin materials. However, these alternatives may not always perform as expected. Testing and refining these products remain necessary. As we push for greener buildings, the path isn’t always straightforward. The journey toward sustainable exterior sheathing is full of lessons learned and future challenges ahead.

Impact of Climate-Resilient Design on Exterior Sheathing Selection

The design of exterior sheathing is evolving rapidly. Climate-resilient design principles have become critical in selecting materials. Architects and builders are increasingly aware of the impacts of changing weather patterns. This awareness is reshaping how buildings are constructed.

Choosing the right exterior sheathing involves considering its thermal performance and moisture resistance. These factors directly influence energy efficiency. Many materials, however, may not perform as expected under extreme conditions. For instance, traditional options can suffer in high humidity or excessive heat. The quest for innovation continues.

Sustainability is key, but it shouldn’t overshadow functionality. Some eco-friendly materials might lack durability. Balancing these aspects can be challenging. The ideal sheathing needs to protect against climate extremes while promoting energy savings. Engaging in trial and error might lead to unexpected results. Evaluating new materials demands ongoing reflection and assessment.

Evaluating the Life Cycle of Sustainable Sheathing Options

The life cycle of sustainable sheathing options is crucial in eco-friendly building practices. Understanding the environmental impact from production to disposal can lead to smarter choices. According to the U.S. Green Building Council, up to 50% of a building’s lifecycle costs are attributed to materials. This statistic indicates careful material selection is essential for sustainability.

When evaluating sheathing materials, think beyond just insulation. Consider the embodied energy. For instance, wood-based options tend to have a lower carbon footprint compared to synthetic alternatives. However, sourcing methods matter. Timber harvested unsustainably can negate benefits. Choose products that use reclaimed materials or certified sources.

Tips: Opt for locally sourced materials whenever possible. This reduces transportation emissions. Moreover, keep an eye on certifications like FSC or Cradle to Cradle. They signal better environmental commitment. Remember, the journey doesn’t end after installation. Assess the end-of-life options. Will the material be recyclable or compostable? Always plan for what happens when the building reaches its lifespan.

Integration of Renewable Resources in Sheathing Production

The integration of renewable resources in exterior sheathing production is a vital trend today. It responds to the pressing need for sustainability in the building industry. According to reports, using materials like bamboo, reclaimed wood, and recycled plastics can reduce carbon footprints significantly. In some cases, using these resources can cut emissions by up to 30%.

However, challenges remain. Not all renewable materials offer the same durability as traditional options. By prioritizing life-cycle assessments, builders can better evaluate the long-term impacts of these materials. Using a mixture of renewable and conventional materials could be a practical solution. This blend can provide better structural integrity while still embracing sustainability.

Tips: Consider sourcing materials locally. This reduces transportation emissions and supports local economies. Look into certifications that ensure materials are genuinely renewable. Always remember, not every "green" product is created equal. Make informed choices based on credible data.

Future Innovations: Smart Technologies in Exterior Sheathing Solutions

The future of exterior sheathing is evolving rapidly, especially with smart technologies. Recent reports indicate that the global smart building market is projected to grow to $650 billion by 2026. This growth is leading to innovative materials that enhance sustainability and energy efficiency.

Smart exterior sheathing solutions are designed to optimize thermal performance. For instance, materials embedded with sensors can monitor temperature and humidity. This data helps in managing energy consumption effectively, allowing for adjustments based on real-time conditions. Some studies suggest that integrating these technologies can lead to energy savings of up to 30%.

Furthermore, there are challenges. Not all smart materials are cost-effective for every project. The initial investment can deter some builders. There is also the question of durability. How well will these materials hold up over time? Improvements are necessary before they become standard in construction. Nonetheless, the potential for innovation in exterior sheathing is immense. With ongoing research, we may soon see solutions that not only meet current needs but anticipate future demands.

2026 Top Trends in Exterior Sheathing for Sustainable Building

Related Posts

-

2025 How to Choose the Right Exterior Sheathing for Your Home

-

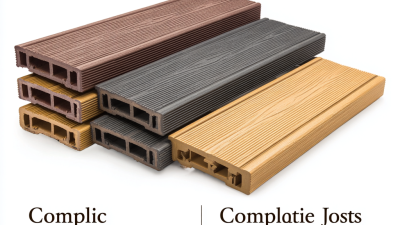

2026 How to Choose the Best Composite Deck for Your Outdoor Space?

-

What are Panel Systems? Benefits, Types, and Uses Explained!

-

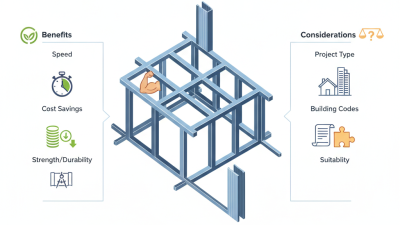

How to Use Light Gauge Steel Framing for Your Next Construction Project?

-

What is Light Gauge Metal Framing and Why Use It?

-

How to Choose the Best Composite Deck Joists for Long-lasting Durability and Performance