How to Build Prefabricated Steel Structures for Your Next Project?

In the realm of construction, the demand for efficiency is ever-increasing. Prefabricated steel structures have emerged as a solution. These structures are not only sustainable but also cost-effective. John Smith, a renowned expert in the prefabricated steel industry, once stated, "Prefabricated steel structures redefine how we think about construction efficiency." His insight underscores the growing significance of these methods.

Building prefabricated steel structures involves careful planning and precision. The process begins with design, which must consider the specific needs of the project. Attention to detail in choosing materials is crucial to ensuring durability. Architects and engineers often collaborate to create safe and effective designs. Yet challenges remain. Some may overlook the advantages of preassembly, resulting in increased on-site work.

The installation phase is another critical aspect. Miscommunication between teams can lead to delays and errors. Proper training and supervision are essential to avoid common pitfalls. As the industry evolves, the importance of prefabricated steel structures will only grow. Embracing this innovation requires constant reflection and adaptation to new practices.

Understanding Prefabricated Steel Structures and Their Benefits

Prefabricated steel structures offer numerous benefits for construction projects. These structures are manufactured in a factory setting. This process ensures precision and quality control. Moreover, it significantly reduces on-site labor costs and project timelines. Builders can avoid many weather-related delays. This aspect makes a considerable difference in project scheduling.

One downside is the initial investment. Prefabricated materials can be more expensive upfront. However, the reduced labor and faster assembly often recoup these costs. This is where careful planning comes in. Evaluating the project's overall budget is essential. Additionally, while these structures are durable, modifications can be challenging once assembled. Flexibility in design during the planning phase is crucial. Consider future needs that may arise post-construction.

Incorporating prefabricated steel structures can lead to an efficient project. They work well for commercial buildings, warehouses, and even homes. Yet, it's vital to collaborate with experienced professionals. This collaboration ensures quality installation and adherence to safety standards. Finding the right balance between cost and quality remains a constant reflection point for project managers. The advantages can be substantial, but so can the challenges.

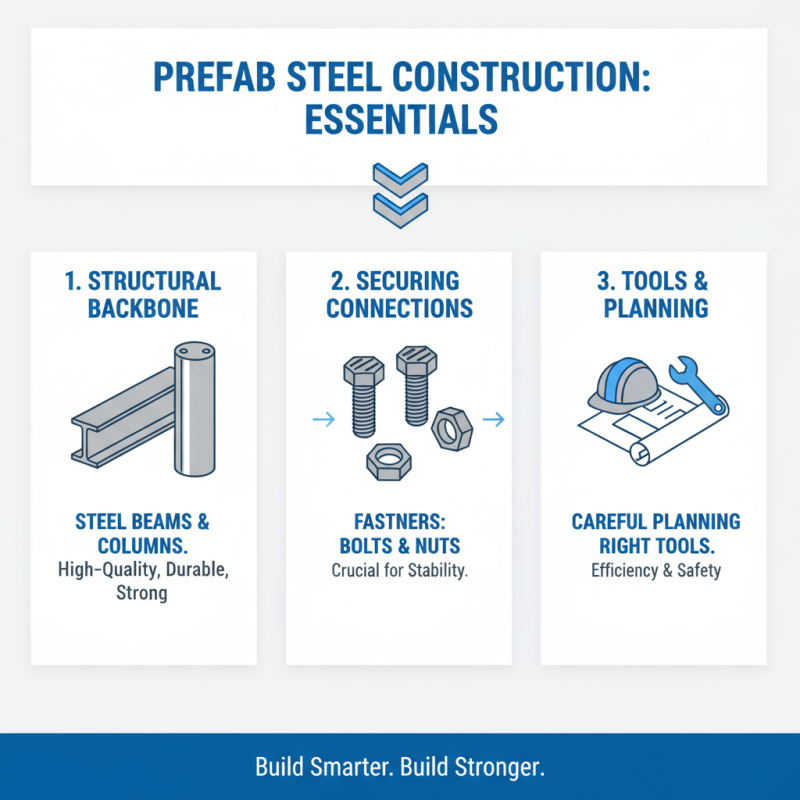

Essential Materials and Tools for Building Steel Structures

Building prefabricated steel structures requires careful planning and the right tools. Start with essential materials like steel beams and columns. They provide the backbone of your structure. High-quality steel ensures durability and strength. Don't forget about fasteners such as bolts and nuts. These are crucial for securing connections.

Tools play a significant role too. A reliable welding machine is key for joining steel pieces together. Look for a cutting tool that can handle thick metal. You might need a drill for bolt holes. Safety gear is also indispensable; wear helmets, gloves, and masks. These items protect you during construction.

Working with steel can be challenging. Mistakes happen. Sometimes welds may not be strong enough or cuts can go awry. Always double-check your measurements. It's easy to overlook details when you're eager to begin. Take your time to ensure everything is precise. Reflection on your process can lead to better results in future projects.

Step-by-Step Guide to Designing Your Prefabricated Steel Structure

Designing a prefabricated steel structure can be an exciting yet challenging process. It starts with a clear understanding of your project requirements. Gather ideas and sketch potential designs that meet your needs. Ensure your structure can withstand local weather conditions. Think about factors like snow loads and wind resistance. Sometimes, initial designs may not work well. It's crucial to adapt and modify them as feedback emerges.

Before you proceed, make sure you have accurate measurements. Take time to calculate dimensions thoroughly. Failing to do so could lead to pitfalls during installation. It’s helpful to consult with professionals. They can offer insights that might otherwise be overlooked. Also, consider the materials carefully. Not all steel is created equal; some might rust quickly, which can lead to costly repairs later.

Once the design is finalized, create detailed plans. Drawings should include all dimensions, connection points, and necessary supports. Think about logistics too. Where will the components be delivered? Who will oversee the assembly? Overlooking these details could delay your project. There might be bumps along the way, and that’s okay. Learning from each challenge is part of the journey.

Techniques for Assembly and Installation of Steel Components

Building prefabricated steel structures requires effective assembly and installation techniques. Steel components are often pre-engineered, which streamlines the construction process. According to the American Institute of Steel Construction, using prefabricated elements can reduce project timelines by up to 30%. Efficient planning is essential.

Tip: Ensure that all welding and connection methods align with industry standards. This helps maintain structural integrity. Proper training for all team members is crucial. Inadequate training may lead to errors during installation, which can be costly and time-consuming.

Focus on logistics. Position materials close to the assembly zone. This minimizes movement and speeds up the workflow. A study by the National Institute of Standards and Technology found that proper layout can improve productivity by 25%. Always check the checklist for missing components before starting. Having a visible plan helps the team stay organized and efficient.

Safety Considerations and Best Practices in Steel Construction

When building prefabricated steel structures, safety must be a priority. According to the Occupational Safety and Health Administration (OSHA), fatalities in the construction industry reached 1,008 in 2021. Many of these accidents occur due to improper handling of materials and equipment. It’s crucial to implement training on safety protocols. Workers should be well-versed in the use of personal protective equipment (PPE) and aware of their surroundings.

Proper design and inspection are essential. The American Institute of Steel Construction (AISC) suggests that steel components should be inspected before installation. This ensures quality and reduces long-term risks. Structural integrity hinges on these factors. Yet, issues like corrosion can arise even in new materials. Regular inspections can catch these problems early.

Furthermore, installation practices should emphasize stability. Each connection must be secured with precision. Inadequate fastening can lead to catastrophic failures. According to a recent study by the Steel Construction Institute, incorrect assembly is a frequent cause of structural collapses. Teams should always double-check their work. Adopting a culture of safety requires ongoing education and reflection on past projects.

How to Build Prefabricated Steel Structures for Your Next Project? - Safety Considerations and Best Practices in Steel Construction

| Dimension | Value |

|---|---|

| Material | Steel |

| Standard Thickness | 6 mm |

| Common Span Length | 12 m |

| Load Capacity | 2000 kg/m² |

| Safety Factor | 1.5 |

| Welding Standard | AWS D1.1 |

| Inspection Frequency | Every 6 months |

| Fire Resistance Rating | 1 hour |

| Common Uses | Warehouses, Factories, Offices |

Related Posts

-

Top Innovations in Steel Metal for 2025 Sustainable Construction and Design

-

2025 Top Trends in Light Gauge Metal Framing: Key Benefits and Innovations

-

2026 Top Trends in Metal Framing Systems for Modern Construction?

-

Ultimate Guide to Choosing the Right Metal Panel for Your Project

-

2025 Top 10 Composite Joists: The Best Choices for Your Construction Projects

-

2026 Top Composite Deck Trends You Need to Know?