Why Choose Light Steel Framing for Your Next Construction Project

In the ever-evolving landscape of construction, the choice of building materials can greatly impact the efficiency, sustainability, and durability of a project. One material that has been gaining significant traction is light steel framing. According to industry expert Dr. Emily Carter, a leading researcher in structural engineering, "Light steel framing provides an innovative solution that combines strength with versatility, making it a top choice for modern construction projects."

As developers and builders seek more efficient and eco-friendly methods, light steel framing presents a compelling alternative to traditional materials. Its lightweight nature allows for quicker assembly and reduced labor costs, while its robust structural properties ensure longevity and resilience against various environmental challenges. Moreover, with an increasing emphasis on sustainable building practices, light steel framing stands out for its recyclability and energy efficiency.

By incorporating light steel framing into upcoming construction projects, stakeholders can leverage significant benefits, from reduced waste to improved design flexibility. As the construction industry continues to adapt to changing demands, the adoption of light steel framing may well represent the future of building techniques, paving the way for innovative and sustainable development.

Benefits of Light Steel Framing in Modern Construction

Light steel framing has become increasingly popular in modern construction due to its numerous benefits that cater to the demands of contemporary building projects. One of the primary advantages of light steel framing is its strength-to-weight ratio, which allows for the reduction of material usage while ensuring structural integrity. According to a report from the Steel Construction Institute, light steel framing can achieve a weight reduction of up to 30% compared to traditional materials without compromising on strength, offering both economic and environmental advantages.

Moreover, light steel framing demonstrates superior resistance to environmental challenges. Steel does not warp, crack, or split as wood does, and it is inherently resistant to pests, such as termites, which can significantly affect the longevity of a building. The National Institute of Standards and Technology has noted that steel structures can endure extreme weather conditions, including high winds and heavy snow loads, thanks to their durability. Additionally, the recyclability of steel contributes to sustainable building practices; around 90% of steel products can be recycled, as highlighted by the American Iron and Steel Institute, resulting in a reduced carbon footprint in construction.

In terms of construction efficiency, light steel framing allows for quicker assembly and reduced labor costs. A study by the International Code Council found that projects utilizing light steel framing can shorten construction time by 20-40% compared to traditional wood framing, making it an attractive option for developers looking to meet tight deadlines. Furthermore, the precision manufacturing process of light steel components ensures high-quality construction with minimal wastage, ultimately leading to a more economical building project.

Benefits of Light Steel Framing in Modern Construction

Key Characteristics of Light Steel Framing Materials

Light steel framing (LSF) has emerged as a preferred choice in modern construction projects due to its versatility and structural advantages. One of the key characteristics of light steel framing materials is their exceptional strength-to-weight ratio. According to a report by the Steel Construction Institute, LSF structures can effectively achieve desired strength with less material than traditional framing methods, resulting in lighter buildings that require less robust foundations. This not only reduces the overall material costs but also minimizes labor and construction time, as the components are easier to handle and install.

Another significant characteristic of light steel framing is its durability and resistance to various environmental factors. Unlike wood, steel is not susceptible to termites, rot, or warping, which ensures the longevity of structures. A survey conducted by the American Iron and Steel Institute indicates that steel structures can last up to 50 years or more with minimal maintenance. Additionally, LSF's inherent fire resistance, owing to steel’s non-combustible properties, provides an added layer of safety, which is crucial in compliance with building codes and insurance standards. These attributes make light steel framing an attractive option for builders seeking both efficiency and reliability in their construction projects.

Comparative Analysis: Light Steel Framing vs. Traditional Methods

Light steel framing (LSF) has emerged as a compelling alternative to traditional construction methods, frequently drawing attention for its robustness, sustainability, and speed of assembly. According to a report by the Steel Construction Institute, LSF can reduce construction time by up to 50% compared to conventional framing techniques. This advantage is especially significant in projects with tight deadlines, allowing contractors to deliver structures faster without compromising quality. Additionally, the lightweight nature of steel reduces the need for heavy equipment, further minimizing costs associated with labor and machinery.

In terms of sustainability, the World Steel Association highlights that around 90% of steel is recyclable, making light steel framing a more environmentally friendly option. Traditional methods may rely on timber, which can contribute to deforestation issues if not sourced sustainably. The energy efficiency of LSF also stands out, with studies indicating that buildings framed with steel can achieve superior insulation performance, leading to reduced heating and cooling costs by up to 30%. Such benefits not only enhance the economic viability of projects but also align with increasing global demands for eco-conscious construction practices.

Comparative Analysis: Light Steel Framing vs. Traditional Methods

| Criteria | Light Steel Framing | Traditional Methods |

|---|---|---|

| Weight | Lightweight | Heavy |

| Construction Speed | Faster | Slower |

| Durability | High (resistant to pests) | Moderate (risk of pests) |

| Cost | Cost-effective in the long term | Higher material costs |

| Eco-friendliness | Recyclable materials | Less recyclable (wood) |

| Insulation | Requires additional insulation | Natural insulation properties |

| Fire Resistance | Non-combustible | Combustible |

Cost-Effectiveness of Light Steel Framing Over Time

Light steel framing has emerged as a popular choice for construction projects due to its notable cost-effectiveness over time. Unlike traditional wood framing, light steel framing offers durability and resistance to various environmental challenges, which translates into lower maintenance costs. Initially, the price of light steel may seem higher, but the long-term savings from reduced repairs and replacements can significantly outweigh the upfront investment. Moreover, its lightweight nature can lead to savings in transportation and handling costs.

**Tips:** When considering light steel framing, be sure to evaluate your project's specific needs. Conduct a thorough cost analysis that includes both initial expenditures and long-term maintenance expenses to ensure you make the most informed choice. Engaging with experienced contractors who specialize in steel framing can also provide valuable insights into maximizing your budget and project efficiency.

In addition to its cost-effectiveness, light steel framing contributes to energy efficiency. Steel is an excellent material for insulation, which can reduce energy bills significantly over time. Proper insulation techniques combined with steel framing result in well-regulated indoor climates, enhancing the comfort of occupants while further contributing to significant savings.

**Tips:** Look into sustainable insulation options that work well with light steel framing to optimize energy efficiency. Utilizing energy modeling software during the design phase can also help predict energy consumption patterns and identify potential savings.

Sustainability and Environmental Impact of Light Steel Framing

Light steel framing is gaining popularity in construction projects due to its significant sustainability benefits and reduced environmental impact. One of the primary advantages of light steel framing is its recyclability. Steel can be recycled multiple times without losing its structural integrity, making it a highly sustainable choice. In contrast to traditional wood framing, which involves deforestation and can contribute to habitat destruction, light steel framing utilizes steel that often includes a high percentage of recycled material. This reduction in resource extraction not only conserves natural ecosystems but also lowers the carbon footprint associated with building materials.

Moreover, light steel framing offers superior energy efficiency. Steel structures can be designed to include advanced insulation techniques that help regulate indoor temperatures, thus lowering energy consumption for heating and cooling. This efficiency extends throughout the building's lifecycle, leading to lower energy bills for occupants and a reduced overall environmental impact. Additionally, the durability of steel means that buildings can withstand harsh weather conditions, minimizing the need for repairs and renovations over time.

By choosing light steel framing for construction projects, builders and developers contribute to a more sustainable future while delivering high-performance structures.

Related Posts

-

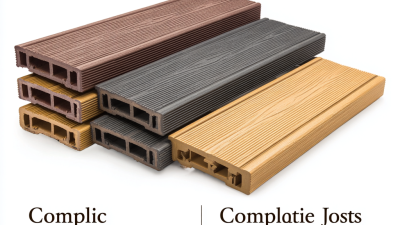

How to Choose the Best Composite Deck Joists for Long-lasting Durability and Performance

-

How to Choose Cold Formed Metal Framing for Your Construction Project

-

Top Reasons to Choose Composite Decking for Your 2025 Outdoor Projects

-

What are Panel Systems? Benefits, Types, and Uses Explained!

-

Why Cold Formed Metal Framing is the Future of Sustainable Construction Solutions

-

2025 How to Choose the Right Exterior Sheathing for Your Home