How to Choose the Right Structural Steel for Your Construction Project?

Choosing the right structural steel for a construction project can be a daunting task. As industry expert John Smith, CEO of Steel Solutions, once said, “Selecting the right steel is crucial for structural integrity.” Structural steel is essential for creating safe and durable buildings. However, many factors complicate this decision.

It's essential to consider characteristics like tensile strength, corrosion resistance, and weight. For instance, ASTM A36 steel is commonly used due to its strength and affordability. However, in severe environments, using weathering steel may be wiser. The need for proper guidance is evident. Many projects fail to meet safety standards simply due to poor material choices.

Choosing structural steel also involves understanding the specific demands of your project. Each construction site is unique. Local building codes may require specific types of steel. These nuances can significantly affect the outcome. Making informed decisions requires research and sometimes expert consultations. Ultimately, attention to detail can prevent costly mistakes.

Understanding the Different Types of Structural Steel Used in Construction

When selecting structural steel for construction projects, it’s crucial to understand the types available. Common types include carbon steel, alloy steel, and stainless steel. Carbon steel is strong and cost-effective. It’s widely used in buildings and bridges. Alloy steel contains additional elements, improving strength and durability. This type is ideal for heavy-duty applications.

Stainless steel offers excellent corrosion resistance. It’s often used in environments exposed to moisture. While it’s more expensive, its longevity can offset initial costs. Each type serves specific needs in construction. Choosing the wrong one can lead to issues. Weight considerations and environmental factors are key.

Architects and engineers sometimes overlook these details. They may prioritize aesthetics over functionality. This can result in structural problems later. Therefore, thorough research is necessary. Assessing the site conditions and loads will help make a better decision. Knowing the right kind of steel can save time and money in the long run.

Types of Structural Steel Used in Construction

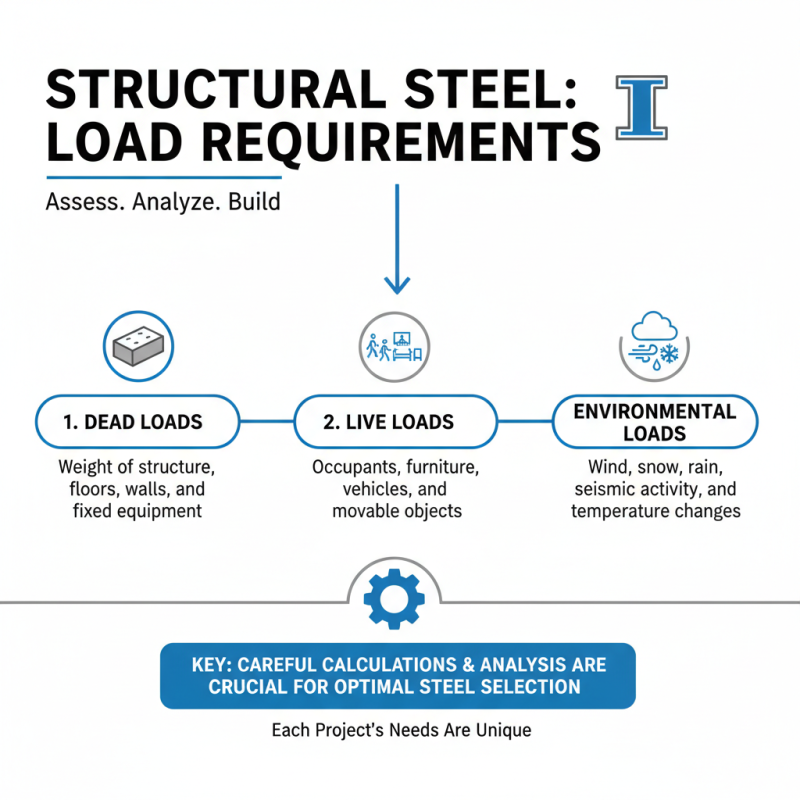

Assessing Load Requirements and Structural Performance Criteria

When it comes to choosing structural steel, assessing load requirements is vital. Each construction project has unique needs. Understanding those needs requires careful calculations and analysis. You need to know the types of loads your structure will face. These include dead loads, live loads, and environmental loads. Each type affects the steel selection process.

Structural performance criteria are equally important. Different projects may require varying levels of durability and strength. For instance, buildings in high-wind areas need stronger materials. Similarly, bridges must endure heavy traffic loads consistently. Choosing the right steel grade ensures safety and longevity. However, these choices often come with trade-offs. A higher strength steel might be costlier and harder to work with. Balancing these factors can be challenging. Engineers must weigh the benefits against their project budgets and timelines, which can sometimes lead to tough decisions.

Evaluating Cost Factors and Budget Constraints for Steel Selection

When evaluating cost factors for structural steel selection, budgeting is crucial. Recent data from the American Iron and Steel Institute indicates that steel prices have seen fluctuations, affecting project costs. In 2023, the average cost per ton of structural steel was approximately $1,200. Yet, this figure can vary. Factors like market demand and material availability play significant roles.

Beyond raw costs, consider fabrication and transportation expenses. Fabrication can add 15-25% to the total cost. Logistics also impact budgets. If steel elements are sourced from distant locations, transportation fees can stack up quickly. Local vendors often offer better long-term pricing, but this isn’t always the best choice. Quality and availability must remain priorities.

Additionally, overlooking the impact of market trends can lead to budgeting pitfalls. Steel demand in construction soared post-pandemic. Prices surged as manufacturers struggled to keep up. Project planners need to monitor price trends closely. Engaging with several suppliers can provide insights into pricing shifts. Be prepared for unexpected expenses, and always have a contingency plan.

Considering Environmental Impact and Sustainability of Structural Steel

When selecting structural steel for a construction project, the environmental impact is crucial. Steel production is energy-intensive and contributes to carbon emissions. It's essential to choose low-impact materials. Some options involve recycled steel, reducing the demand for new raw materials. This not only conserves resources but also cuts waste.

Sustainability goes beyond materials. The lifecycle of steel is important too. Consider how the steel will be used, maintained, and eventually disposed of. Structures designed for longevity will lessen the need for future materials. Temporary structures can also opt for lighter, less resource-heavy options. Each decision impacts the environment.

However, achieving sustainability is challenging. Not all recycled steel has the same quality. Sourcing local materials can sometimes be more beneficial than recycling. Balancing cost, strength, and sustainability is not always easy. Questions arise around the true impact of these choices. It's vital to keep learning and adapting practices in the construction industry. Every small step counts toward a greener future.

How to Choose the Right Structural Steel for Your Construction Project? - Considering Environmental Impact and Sustainability of Structural Steel

| Steel Type | Carbon Content (%) | Strength (MPa) | Recyclability (%) | Environmental Impact Rating |

|---|---|---|---|---|

| Mild Steel | 0.05 - 0.25 | 250 - 400 | 90 | Low |

| High Strength Low Alloy (HSLA) | 0.05 - 0.20 | 400 - 700 | 90 | Medium |

| Stainless Steel | 0.03 - 0.10 | 480 - 950 | 60 | High |

| Carbon Steel | 0.05 - 2.0 | 300 - 600 | 85 | Medium |

| Recycled Steel | Varies | 250 - 600 | 100 | Very Low |

Consulting Industry Standards and Building Codes for Compliance

Choosing the right structural steel involves understanding industry standards and building codes. Compliance with these regulations ensures safety and longevity. Various organizations, such as the American Institute of Steel Construction (AISC), provide detailed guidelines. For example, AISC's "Steel Construction Manual" offers insights into material properties and design considerations. Adhering to these standards can prevent costly mistakes.

Local building codes also play a crucial role. They vary by region and dictate specific requirements. For instance, some areas may mandate seismic considerations for high-rise buildings. Ignoring these codes might lead to project delays or costly reworks. In a 2021 study, compliance with local codes was linked to a 30% reduction in structural failures during earthquakes.

It's essential to consider the source of the steel. Not all suppliers meet the same standards. Some may offer lower grades that are not compliant with recommended practices. A 2022 report indicated that about 15% of construction projects encountered issues due to non-compliant materials. This highlights the importance of diligent supplier vetting. Always review certifications and documentation before making a purchase.

Related Posts

-

How to Install Light Gauge Metal Framing for Your Construction Project?

-

2026 Best Steel Metal Products for Durability and Sustainability?

-

2026 Top Composite Deck Trends You Need to Know?

-

Top Benefits of Using Steel Posts in Construction and Landscaping?

-

2025 Top 10 Innovative Steel Metal Products Redefining Industry Standards

-

What is Steel Framing and How It Transforms Construction Efficiency and Durability