How to Choose the Right Construction Steel for Your Project?

Choosing the right construction steel for your project is crucial. The construction industry has seen a significant shift in material preferences due to advances in technology and sustainability. According to a recent report by the World Steel Association, the global steel demand is projected to reach 1.7 billion metric tons by 2025. This growth is driven by urbanization and infrastructure development.

Renowned structural engineer, Dr. James Parker, emphasizes, “Selecting the correct construction steel can enhance a structure’s durability and longevity.” His insight reflects the industry's shift toward more reliable steel grades.

Various factors influence the choice of construction steel, including tensile strength, corrosion resistance, and weldability. Understanding these properties can save costs and avoid future project complications. Yet, many fail to pay enough attention to these aspects, leading to structural issues later. Balancing these details is vital for successful project outcomes.

Understanding the Different Types of Construction Steel Available

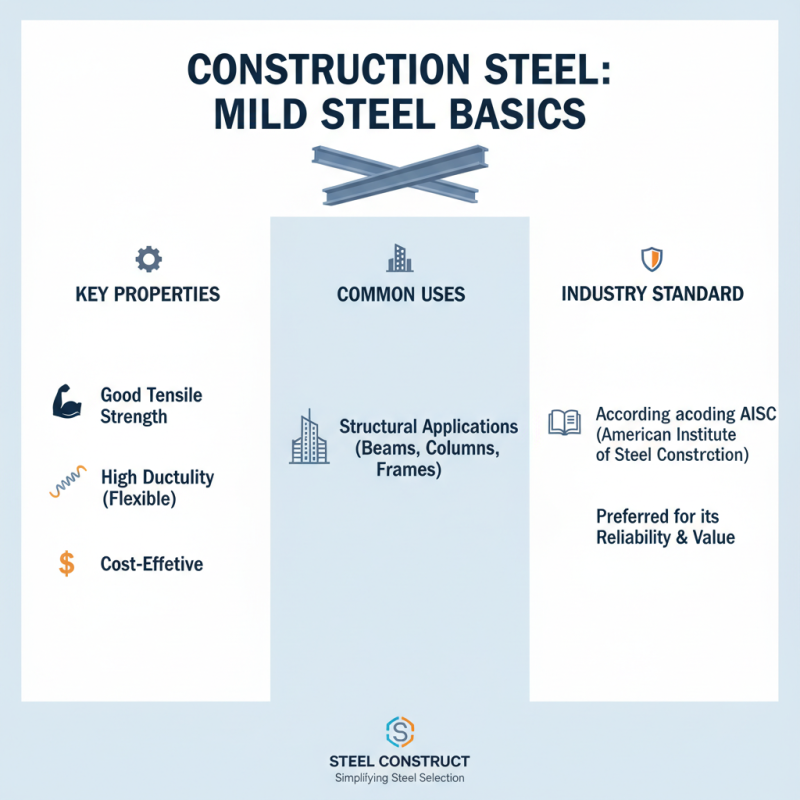

When selecting construction steel, understanding the different types is crucial. Mild steel is commonly used for structural applications. It has good tensile strength and ductility. According to the American Institute of Steel Construction (AISC), mild steel is often chosen for its cost-effectiveness.

High-strength low-alloy (HSLA) steel is another option. It offers enhanced mechanical properties without the weight. Reports indicate that HSLA steel can provide up to 30% greater strength compared to mild steel. This feature can save on material costs and reduce overall weight, making it ideal for specific designs.

Stainless steel is prized for corrosion resistance. It is often used in environments exposed to moisture or chemicals. According to a study by the National Association of Home Builders (NAHB), using stainless steel can increase the longevity of a project. However, it comes at a higher cost. This trade-off between initial expense and long-term durability is a key consideration. The decision should reflect project goals, budget constraints, and anticipated environmental conditions.

Factors to Consider When Selecting Construction Steel for Your Project

Choosing the right construction steel is crucial for any building project. Several factors must be considered before making a decision. One key aspect is the type of steel. Structural steel grades vary, impacting strength and durability. Common grades include S235 and S355, each suited for different applications. According to industry standards, S355 steel offers better tensile strength, making it ideal for heavy-load structures.

Cost is another major consideration. The price of steel fluctuates, influenced by market demand and production rates. A recent report indicated that global steel prices have risen by 15% in the last year due to supply chain issues. It's vital to evaluate both budget constraints and the long-term benefits of using higher-grade steel.

Tip: Always analyze your project's specifications. This can prevent costly mistakes later. Review past projects that utilized specific steel types. Understand how those choices affected durability and safety. Balancing cost with quality can lead to a more successful outcome.

When selecting construction steel, think about the environment. Steel's capacity for recycling is a strong advantage. Choosing recyclable options can minimize waste. However, not all steel is created equal in this regard. Careful research is necessary to make informed choices. Always ensure that your steel supplier adheres to sustainability practices. Doing so enhances your project's overall impact.

Steel Strength Comparison for Construction

Evaluating the Strength and Durability Requirements for Steel

When selecting construction steel, evaluating strength and durability is crucial. The type of steel you choose directly influences the longevity and safety of your project. According to the American Institute of Steel Construction, structural steel can endure immense loads, making it a preferred choice for buildings and bridges. It's vital to understand the specific requirements of your project, as different grades of steel offer varying strengths and resistance to environmental factors.

Tips: Always consider the environmental conditions at the construction site. Will the steel be exposed to corrosive elements, like saltwater? If yes, opting for galvanization can help enhance durability.

The tensile strength of steel often dictates its application. Mild steel has a yield strength around 250 MPa, making it suitable for many projects. However, for high-load structures, consider high-strength low-alloy (HSLA) steel, which offers better performance with a yield strength exceeding 300 MPa. Choosing the right grade can also prevent future issues, such as fatigue under cyclical loads.

Tips: Conduct a thorough analysis of stress factors your structure will face. Regular maintenance checks can also help identify weaknesses before they become threats. Always question whether the steel meets all necessary standards for your specific application.

How to Choose the Right Construction Steel for Your Project? - Evaluating the Strength and Durability Requirements for Steel

| Steel Type | Yield Strength (MPa) | Tensile Strength (MPa) | Durability | Common Applications |

|---|---|---|---|---|

| Mild Steel | 250 | 400 | Moderate | Construction, Automotive |

| High Strength Low Alloy (HSLA) | 350 | 600 | High | Bridges, Heavy Equipment |

| Stainless Steel | 200 | 550 | Very High | Marine, Food Processing |

| Carbon Steel | 200 | 500 | Moderate | Construction, Manufacturing |

| Alloy Steel | 300 | 700 | High | Automotive, Aerospace |

Assessing Corrosion Resistance and Environmental Impact of Steel

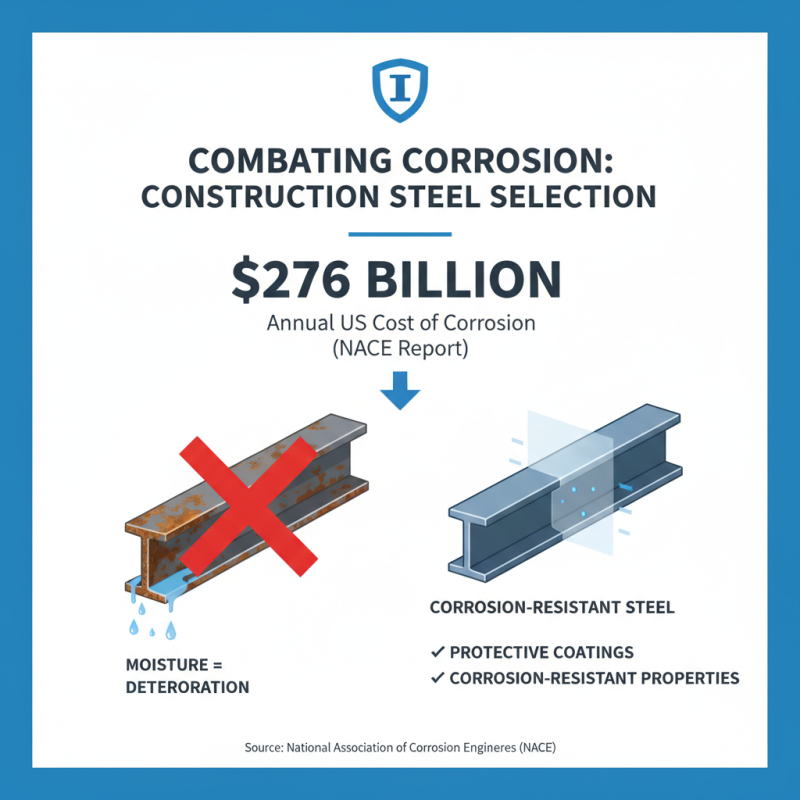

When selecting construction steel, assessing corrosion resistance is vital. Steel's exposure to moisture can result in deterioration. According to a report by the National Association of Corrosion Engineers, corrosion costs the U.S. economy approximately $276 billion annually. This underscores the importance of choosing steel with appropriate protective coatings or corrosion-resistant properties.

Environmental impact should also be considered. Manufacturing steel contributes significantly to carbon emissions. Data from the World Steel Association shows that the industry accounted for 7% of total global CO2 emissions in 2020. Although advancements like electric arc furnaces are improving sustainability, the challenge remains. Project managers must weigh the durability of steel against its environmental footprint.

Designing for the long term often involves trade-offs. Corrosion-resistant materials may cost more upfront. However, they can save money over time by reducing maintenance. While galvanized steel offers better protection, it may not be suitable for all environments. Each project demands careful evaluation of materials to ensure they meet specific conditions. Making informed choices is essential for both economic and environmental reasons.

Cost Considerations in Choosing Construction Steel Materials

When choosing construction steel, cost plays a crucial role. In recent studies, the average cost of construction steel has surged, influenced by factors like production rates and raw material prices. Steel prices can fluctuate yearly. In 2023, the average price per ton was reported to be around $950, a noticeable rise from previous years. This escalation can impact your project budget significantly.

Tips: Always compare quotes from different suppliers. You might find better prices and services. Additionally, consider bulk purchasing to save money in the long run.

Consider the type of steel for your project. Common options include carbon steel, stainless steel, and alloy steel. Each has different price points and suitability for specific applications. Carbon steel is typically less expensive, while stainless steel can double or triple the upfront costs. However, its durability may offer savings over time.

Costs also include installation and transportation. Often overlooked, these expenses can exceed the material costs. Make sure to account for them early to avoid surprises later. Balancing cost with quality is essential. Remember, cheap steel may lead to costly repairs or replacements. Choose wisely.

Related Posts

-

Top Innovations in Steel Metal for 2025 Sustainable Construction and Design

-

How to Choose the Right Structural Steel for Your Construction Project?

-

How to Build Prefabricated Steel Structures for Your Next Project?

-

Best Deck System Solutions for Enhanced Outdoor Living?

-

How to Use Steel Framing for Your Construction Projects?

-

2026 How to Choose the Best Composite Deck for Your Outdoor Space?