10 Essential Tips for Using Precast Concrete in Your Next Project

Precast concrete is rapidly emerging as a preferred choice in the construction industry, largely due to its versatility, durability, and efficiency. According to the American Concrete Institute, the use of precast concrete has seen a significant increase, with a projected industry growth rate of 5.2% annually through 2028. This surge can be attributed to its ability to meet tight schedules while maintaining superior quality compared to traditional building methods. Furthermore, the inherent sustainability of precast concrete, which reduces waste and lowers carbon emissions during production, contributes to its rising popularity amidst growing environmental concerns.

Industry expert Dr. Emily Tran, a leading authority on precast concrete applications, emphasized the material's advantages by stating, “The modular nature of precast concrete not only streamlines the construction process but also provides architects and builders with unparalleled design flexibility.” This flexibility allows for innovative structural solutions that can cater to diverse project requirements, from commercial buildings to infrastructure projects. Incorporating essential tips for using precast concrete correctly can greatly enhance project outcomes, ensuring not only structural integrity but also aesthetic appeal and cost-effectiveness. As we explore the ten essential tips for utilizing precast concrete in your next project, we will illuminate how to maximize its benefits within the modern construction landscape.

Understanding Precast Concrete: Benefits and Applications

Precast concrete has emerged as a preferred material in modern construction due to its numerous advantages and diverse applications. One significant benefit of precast concrete is its consistent quality, achieved through controlled factory conditions. This process minimizes variations that often occur during traditional on-site pouring methods. Additionally, precast elements can be produced rapidly, allowing for shorter construction timelines while ensuring structural integrity. Moreover, the use of precast concrete can enhance sustainability in building projects, as it allows for efficient use of raw materials and reduces waste.

The applications of precast concrete are vast, ranging from residential homes to large-scale infrastructure projects. It can be utilized for walls, floors, and even intricate architectural features, demonstrating versatility in design and functionality. Precast components are not only durable but also offer excellent thermal and acoustic properties, making them suitable for various environments. Their ability to adapt to different climates and conditions further underscores the material’s practicality in meeting the specific needs of any project. Ultimately, understanding the benefits and applications of precast concrete can lead to more innovative and efficient construction methods.

10 Essential Tips for Using Precast Concrete in Your Next Project

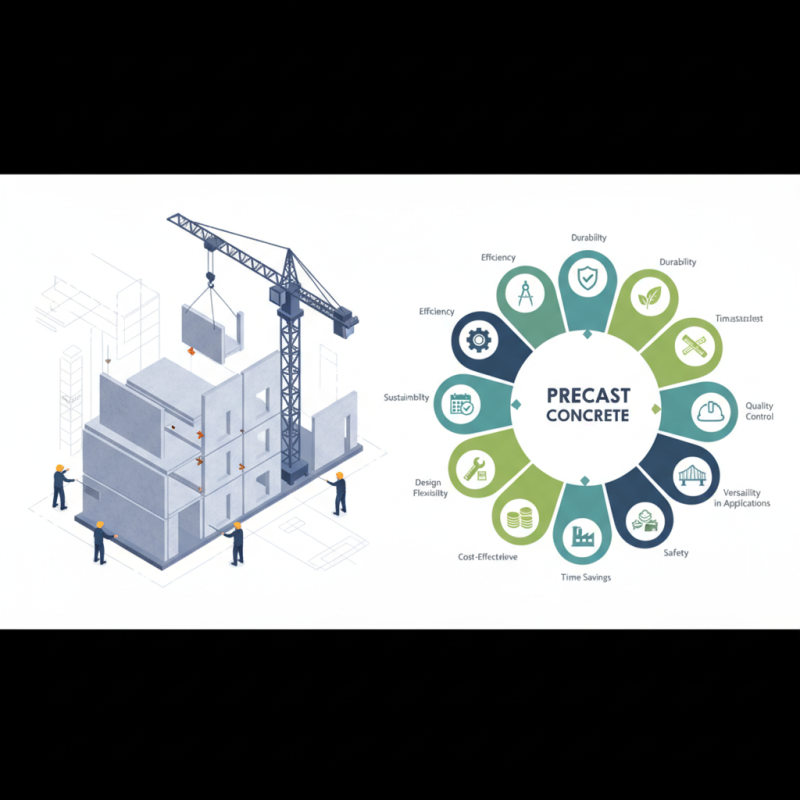

This chart illustrates the importance of various features of precast concrete in construction projects. Each feature is rated based on its significance, helping project managers prioritize aspects when employing precast concrete solutions.

Choosing the Right Precast Concrete Products for Your Project

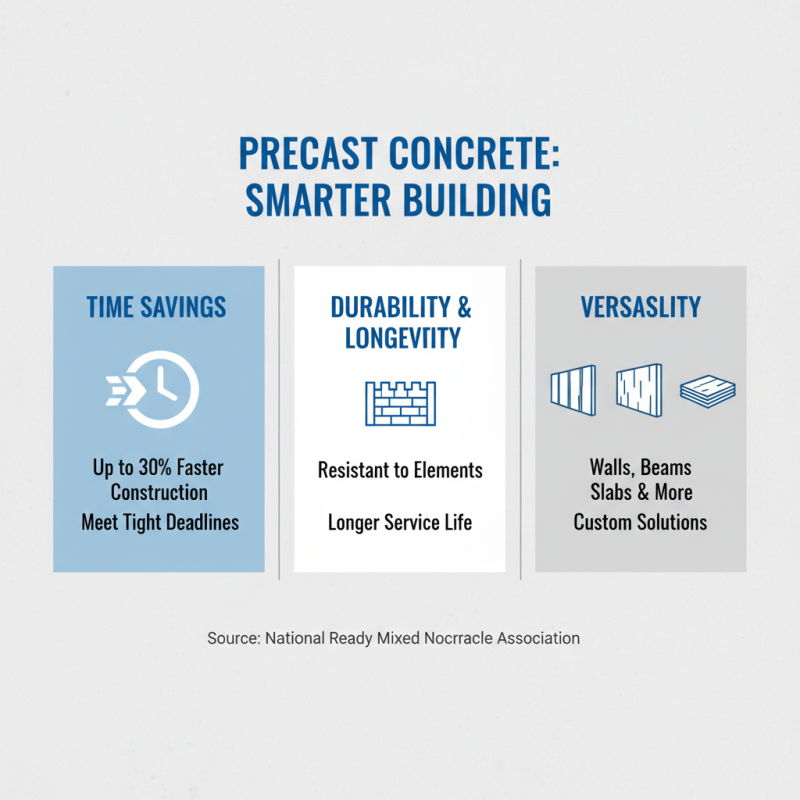

When embarking on a construction project, selecting the right precast concrete products can significantly influence both the efficiency and longevity of the build. According to the National Ready Mixed Concrete Association, the use of precast concrete can reduce construction time by up to 30%, making it an attractive option for contractors looking to meet tight schedules. Understanding the specific needs of your project is essential in choosing the correct precast components, whether they are walls, beams, or slabs.

Tip 1: Assess the structural requirements of your project before choosing products. Different precast concrete options come with varying load-bearing capacities that must align with your design specifications. For example, if you're building a structure that requires significant thermal mass, elements such as insulated precast panels could provide both strength and energy efficiency.

Tip 2: Consider the environmental impact of your choices. A report by the Global Cement and Concrete Association indicates that using precast concrete can lead to lower embodied carbon emissions compared to traditional alternatives, attributed to controlled manufacturing environments and reduced waste. Selecting products that incorporate recycled materials can further enhance sustainability while meeting modern construction standards.

In sum, making informed decisions on precast concrete selections not only ensures structural integrity but also aligns with cost-efficiency and environmental responsibility.

Tips for Planning and Designing with Precast Concrete

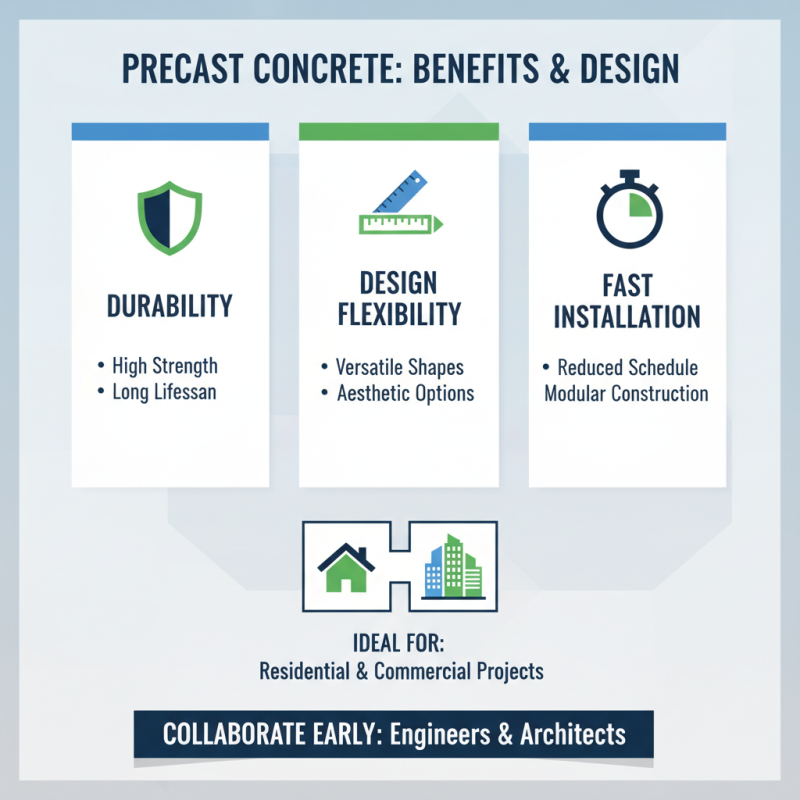

When planning and designing with precast concrete, the first step is to thoroughly understand the material’s benefits and limitations. Precast concrete offers high durability, design flexibility, and fast installation times. These advantages make it ideal for a variety of projects, ranging from residential homes to commercial buildings. Be sure to collaborate with engineers and architects early in the design phase to optimize the use of precast elements, ensuring that structural integrity and aesthetic goals are met.

Another crucial tip is to account for logistics during the design process. Precast components are typically manufactured off-site, which means careful planning for transportation and placement on the job site is essential. This includes considering the weight and size of the precast elements, as well as any required lifting equipment. Engaging with contractors to understand site limitations and access can streamline the installation phase and reduce delays.

Additionally, when incorporating precast concrete into your design, consider the finishing options available. Precast can be designed with various textures, colors, and patterns, allowing for creative expression while maintaining functionality. By blending different finishes, you can achieve a unique look that caters to the project’s vision, making precast not only a practical choice but also a stylish one.

Working with Contractors and Suppliers for Precast Projects

When embarking on a precast concrete project, collaboration with contractors and suppliers is crucial for success. According to the National Precast Concrete Association, utilizing precast concrete can reduce construction time by up to 50%, but only if all parties are well coordinated. Clear communication with suppliers regarding project specifications and timelines can lead to streamlined operations and minimize delays. Engaging contractors early in the process ensures that their expertise informs design choices, optimizing the benefits of precast materials.

One essential tip for working with contractors is to establish a comprehensive project timeline that integrates the design, production, and installation phases of precast elements. This allows for the adjustment of schedules to accommodate for curing times and transport logistics, crucial for maintaining efficiency. Additionally, fostering a collaborative atmosphere where contractors provide feedback on precast designs can enhance the project's overall quality and effectiveness.

It’s also vital to ensure that all suppliers understand the project’s specifications. This alignment helps avoid miscommunications that can lead to costly setbacks. Incorporating regular check-ins with suppliers throughout the project lifecycle is beneficial. Emphasizing these collaborative efforts can elevate the reliability of precast concrete applications, paving the way for innovative uses such as sustainable design practices—an increasingly critical aspect of the construction industry today.

10 Essential Tips for Using Precast Concrete in Your Next Project

| Tip No. | Tip | Details | Best Practices |

|---|---|---|---|

| 1 | Choose Quality Suppliers | Ensure your suppliers have a good reputation and track record. | Research supplier reviews and ratings. |

| 2 | Plan Ahead | Schedule your precast deliveries well in advance. | Develop a timeline for project milestones. |

| 3 | Understand Site Requirements | Know your site’s access and conditions for delivery and installation. | Conduct a thorough site analysis before construction. |

| 4 | Train Your Team | Ensure all workers are trained on precast handling and installation. | Conduct safety and handling training sessions. |

| 5 | Communicate Clearly | Maintain open lines of communication with contractors and suppliers. | Use project management tools for better collaboration. |

| 6 | Quality Control | Implement strict quality control measures for precast elements. | Regular inspections and testing during production. |

| 7 | Consider Design Flexibility | Design precast components for ease of assembly and flexibility. | Collaborate with architects for innovative designs. |

| 8 | Manage Costs Effectively | Keep track of costs and budget allocated for precast materials. | Regularly compare quotes from different suppliers. |

| 9 | Review and Adapt | After project completion, review processes for future improvements. | Gather feedback from all stakeholders involved. |

| 10 | Stay Updated | Follow industry trends and new technologies in precast concrete. | Subscribe to industry publications and attend conferences. |

Best Practices for Installation and Maintenance of Precast Concrete

When it comes to the installation and maintenance of precast concrete, following best practices is crucial to ensure longevity and structural integrity. One essential tip is to ensure proper site preparation before installation. This involves ensuring a level foundation and addressing any drainage issues, as inadequate site conditions can compromise the stability of precast elements. Additionally, always check each piece for damage before installation, as any defects could lead to significant problems later on.

Proper handling during installation is equally important. It is advisable to use appropriate lifting techniques and equipment to minimize the risk of damage during transport and placement. Employing trained professionals familiar with precast concrete is invaluable, as they can effectively manage the complexities associated with alignment and securing each element in place. Once installed, routine maintenance is vital; consider scheduling inspections to identify early signs of wear or potential issues, addressing them promptly to avoid costly repairs down the line.

Another key maintenance tip is to keep the precast surfaces clean and free from debris, which can lead to deterioration over time. Regularly wash surfaces and inspect for any signs of moisture penetration, which can cause damage if not addressed. By adhering to these best practices for installation and maintenance, you can significantly enhance the performance and durability of your precast concrete components throughout the lifespan of your project.

Related Posts

-

Top 10 Benefits of Precast Concrete for Modern Construction Projects

-

Top Reasons to Choose Composite Decking for Your 2025 Outdoor Projects

-

Why Cold Formed Metal Framing is the Future of Sustainable Construction Solutions

-

Why Choose Light Steel Framing for Your Next Construction Project

-

How to Choose Cold Formed Metal Framing for Your Construction Project

-

What is Steel Framing and How It Transforms Construction Efficiency and Durability