How to Install Light Gauge Metal Framing for Your Construction Project?

Light gauge metal framing has gained significant traction in the construction industry. A recent report from the Metal Construction Association outlines that this method has seen a 20% increase in popularity over the past five years. This shift is largely due to its lightweight nature and resistance to moisture and pests, which traditional materials often fall short in addressing. With many builders seeking efficiency, light gauge metal framing offers clear advantages.

Installation of light gauge metal framing requires attention to detail. While it can minimize labor costs, errors in setup can lead to structural issues. In 2022, improper framing practices accounted for approximately 30% of all construction delays, highlighting the importance of following guidelines carefully. Poor installation not only affects project timelines, but also compromises safety and durability. Therefore, meticulous planning and execution are crucial for achieving the desired outcomes when utilizing this innovative approach in construction projects.

Understanding Light Gauge Metal Framing: An Overview

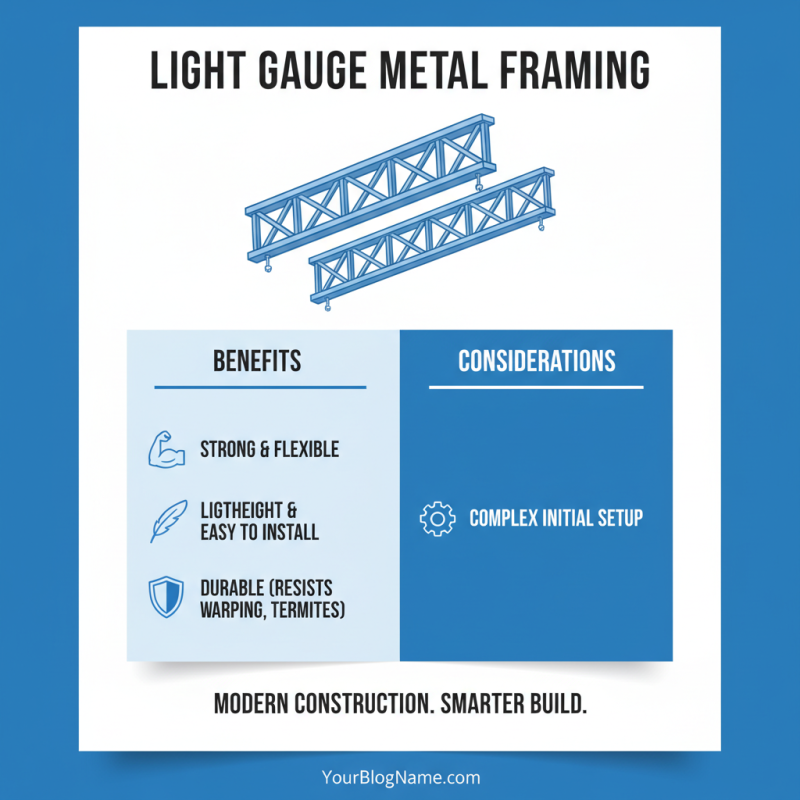

Light gauge metal framing offers a modern solution for construction projects. This system uses thin steel members, providing strength and flexibility. It’s increasingly popular due to its lightweight nature and ease of installation. Builders appreciate that it resists warping and termites, making it durable. However, the complexity of the initial setup can be daunting.

Understanding the components is crucial. Studs, tracks, and connectors form the backbone of this framing system. The studs typically come in various widths and thicknesses, affecting load-bearing capacity. Working with precise measurements is vital, as even a small mistake can lead to major issues later. Using tools designed for metal framing can help, but they require practice.

While metal framing is efficient, it demands attention to detail. Ensuring that all connections are secure cannot be overlooked. Often, builders rush through this stage, which can lead to structural failures. Conducting regular inspections during and after installation helps mitigate risks. Striking a balance between speed and accuracy is essential for a successful project.

Essential Tools and Materials for Metal Framing Installation

When installing light gauge metal framing, having the right tools and materials is critical. Industry studies show that using high-quality materials can significantly reduce project rework by up to 40%. Key tools include metal studs, tracks, and connectors. These components ensure strong structural integrity. Additionally, a level and stud finder help maintain precision during installation.

In terms of materials, choosing the right gauge is vital. Most steel studs range from 20 to 25 gauge. Thicker studs provide stronger support but can be heavier. A mistake in selecting gauge can lead to structural weaknesses. While lighter gauge might save costs, it could cause problems later.

Don't overlook the importance of safety gear. Personal protective equipment like gloves, goggles, and hard hats is essential. They protect workers from potential injuries during assembly. Errors can arise from neglecting safety, so regular safety checks are necessary. Consider training sessions for workers on proper techniques. This enhances efficiency and minimizes costly mistakes.

Step-by-Step Guide to Installing Light Gauge Metal Studs

Installing light gauge metal studs is a practical choice for many construction projects. These materials are known for their durability and efficiency. According to the Steel Framing Alliance, using metal studs can reduce construction time by up to 25%. This allows projects to stay on schedule and under budget.

Start by gathering your tools. You'll need a metal stud saw, a level, and a measuring tape. Mark the floor and ceiling where the studs will go. Make sure to measure accurately. It’s important to double-check your measurements before cutting the studs. A simple mistake can lead to wasted materials and time.

When installing the studs, secure each one with screws. Maintain even spacing, typically 16 inches apart, as recommended by the Gypsum Association. Be mindful of the sound and vibration. Excessive noise can indicate incorrect installation. Always ensure safety measures are in place while working with metal materials. This method can be challenging, but the results are rewarding.

Techniques for Securing and Bracing Metal Framing Structures

Securing and bracing metal framing structures is crucial for stability. Proper techniques can greatly enhance the overall integrity of your project. Start by installing vertical studs. Ensure they are spaced correctly, typically 16 or 24 inches apart. Use a level to maintain consistency. A slight tilt can lead to larger issues later.

Next, add horizontal track members. These will help connect the vertical studs. When screwing them into place, ensure they are tight but not overdone. Over-tightening can warp the metal. Consider using diagonal braces for additional support. These should be installed at strategic angles to share the load evenly, preventing sway.

It's essential to avoid common mistakes. Not checking for level can skew your entire framework. Also, neglecting to inspect for any damaged pieces before installation can lead to problems. Each step deserves attention. Small oversights can have big consequences later on. Take your time and be thorough. Quality work now will pay off in the long run.

Light Gauge Metal Framing Installation Techniques

This chart illustrates the effectiveness ratings of various techniques used in light gauge metal framing installations. A higher rating indicates a more effective technique in securing and bracing metal framing structures.

Common Mistakes to Avoid When Installing Metal Framing

When installing light gauge metal framing, it's easy to overlook some critical details. One common mistake is misalignment. If frames are not aligned properly, it can lead to uneven walls. This can affect the entire structure. Check your measurements frequently. Use a level to ensure everything is straight. Small errors can lead to significant issues down the line.

Another frequent error is forgetting to secure the metal studs correctly. Failing to use the right screws can cause instability. Proper fasteners provide the necessary strength for a durable frame. Pay close attention to installation patterns. Inconsistent placements can weaken structural integrity. It's essential to maintain a consistent spacing throughout the project.

Lastly, many people underestimate the importance of safety gear. Neglecting personal protective equipment can lead to accidents. Metal framing can be sharp and hazardous. Always prioritize safety while working. Taking a few extra moments to ensure safety can prevent injuries. Remember that time spent on careful installation will pay off in the long run.

Related Posts

-

What is Light Gauge Steel Framing and Its Benefits for Modern Construction

-

How to Choose the Best Composite Deck Joists for Long-lasting Durability and Performance

-

What is the Best Design Panel for 2026 Top Trends?

-

2026 Top Trends in Metal Framing Systems for Modern Construction?

-

Top Benefits of Using Steel Posts in Construction and Landscaping?

-

2026 Best Steel Metal Products for Durability and Sustainability?