What is Light Gauge Metal Framing and Why Use It?

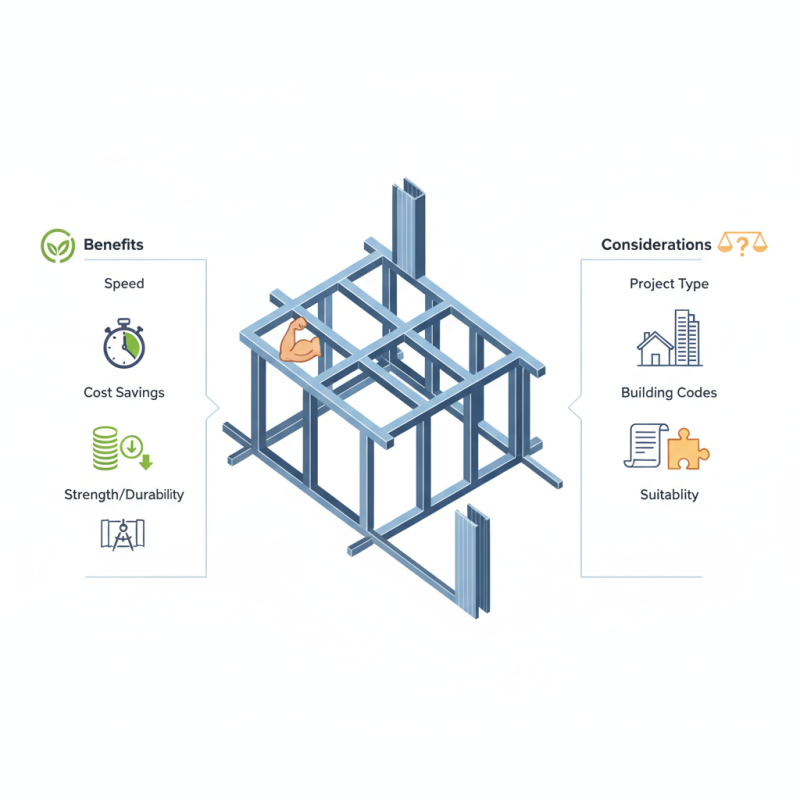

Light gauge metal framing is a construction method that uses thin steel sections. It offers a variety of benefits that appeal to builders and architects alike. This technique provides structural support while minimizing weight. The use of light gauge metal reduces the overall material needed, leading to cost savings and efficiency.

In recent years, light gauge metal framing has gained popularity in residential and commercial projects. This trend reflects a shift towards durable and sustainable building materials. Builders appreciate the speed of installation and fewer labor requirements. The precision of light gauge metal also allows for more flexible design possibilities.

However, some may question its suitability for all types of structures. It’s important to consider specific project needs and local building codes. Not every project will benefit equally from this method. As you explore light gauge metal framing, weighing both its advantages and limitations is crucial for informed decision-making.

What is Light Gauge Metal Framing?

Light gauge metal framing is a construction method that utilizes thin sheets of steel. This technique has gained popularity in recent years, especially in commercial and residential projects. Builders choose this method for its durability and lightweight characteristics. Light gauge frames are easy to transport and install, making them efficient.

This construction method also provides resistance to moisture, termites, and fire. Unlike wood, metal frames do not warp or shrink, which can lead to structural issues over time. However, working with metal framing requires precision. The connections must be properly secured to ensure stability. Mistakes in measurements can lead to costly corrections later.

There are challenges in using light gauge metal, such as the need for specialized tools. It can be noisy during installation, which may disturb neighboring areas. Attention should be paid to insulation, as steel conducts heat and cold. Despite these hurdles, many find that the benefits outweigh the drawbacks. It is a modern choice for innovative designs and long-lasting structures.

What is Light Gauge Metal Framing and Why Use It?

| Dimension | Details |

|---|---|

| Material | Steel |

| Thickness | 20 to 12 gauge |

| Applications | Residential & Commercial Construction |

| Advantages | Lightweight, Cost-effective, Durable, Resistant to Shrinkage |

| Installation Time | Faster than traditional materials |

| Sustainability | Recyclable |

The Materials Used in Light Gauge Metal Framing

Light gauge metal framing is increasingly popular in construction. It primarily uses thin sheets of steel, shaped into studs and tracks. This material offers strength and durability. Builders appreciate its lightweight nature, making it easy to handle. Moreover, it resists pests and rot, unlike traditional wood framing.

When considering materials for light gauge metal framing, steel is the main choice. It's available in various thicknesses, impacting overall sturdiness. Calcium silicate boards or gypsum panels often cover the steel structure, adding fire resistance. Connections may require specialized fasteners. However, skillful installation is crucial; poor joints can lead to structural issues.

Recycling also plays a significant role in the choice of materials. Steel can be reused multiple times, reducing waste. Some may overlook this environmental aspect, focusing solely on costs. Additionally, the initial investment might seem high, but long-term savings in maintenance can counterbalance that. Exploring different materials is essential, yet it’s vital to reflect on their implications for the entire project.

Light Gauge Metal Framing Materials Usage

This chart illustrates the percentage usage of various materials in light gauge metal framing construction.

Benefits of Using Light Gauge Metal Framing

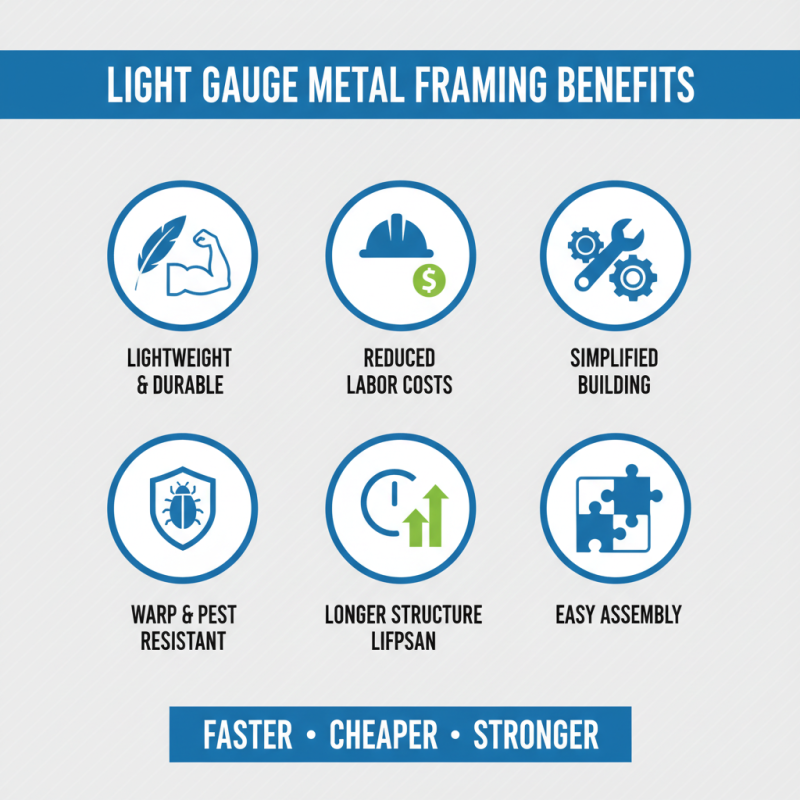

Light gauge metal framing offers numerous advantages in construction. It is lightweight yet durable. This combination reduces labor costs and simplifies the building process. The materials resist warping and pests, contributing to a longer lifespan for structures. For many projects, the ease of assembling light gauge metal framing is a significant benefit. Less time on-site means lower expenses.

In addition to efficiency, light gauge metal framing is highly adaptable. It allows for creative designs and can accommodate various architectural styles. This flexibility is appealing to architects and builders alike. However, not every project may benefit equally from its use. Sometimes, the initial costs can be higher compared to traditional framing. This aspect requires careful consideration.

Moreover, while light gauge framing is strong, it may not always handle certain loads as effectively as wood. Builders need to assess the structural requirements of each project. They must evaluate whether the benefits outweigh potential challenges. These reflections can guide better decision-making in material selection.

Applications of Light Gauge Metal Framing in Construction

Light gauge metal framing is a versatile choice in modern construction. It is commonly used in both residential and commercial buildings, providing structural integrity and durability. Due to its lightweight nature, it can be easily transported and handled on-site. This material allows for quicker installation, which is crucial for tight project timelines. Its resistance to pests and termites makes it increasingly popular in areas vulnerable to such issues.

This framing method sees widespread application in interior wall systems, roofs, and even modular constructions. Buildings often incorporate it for fire safety and reduced weight load. Lightweight metal studs can fit seamlessly into various architectural designs, streamlining the construction process. Many builders appreciate the ease of cutting and adjusting these materials to suit specific layouts.

However, while light gauge metal framing has many advantages, it requires careful planning. Issues can arise if the framework is not adequately anchored or aligned. Improper installation may lead to structural problems later. Some workers may struggle with the precise connections needed. Ongoing training and practice can help overcome these challenges, ensuring a successful finish product.

Comparing Light Gauge Metal Framing with Traditional Framing Methods

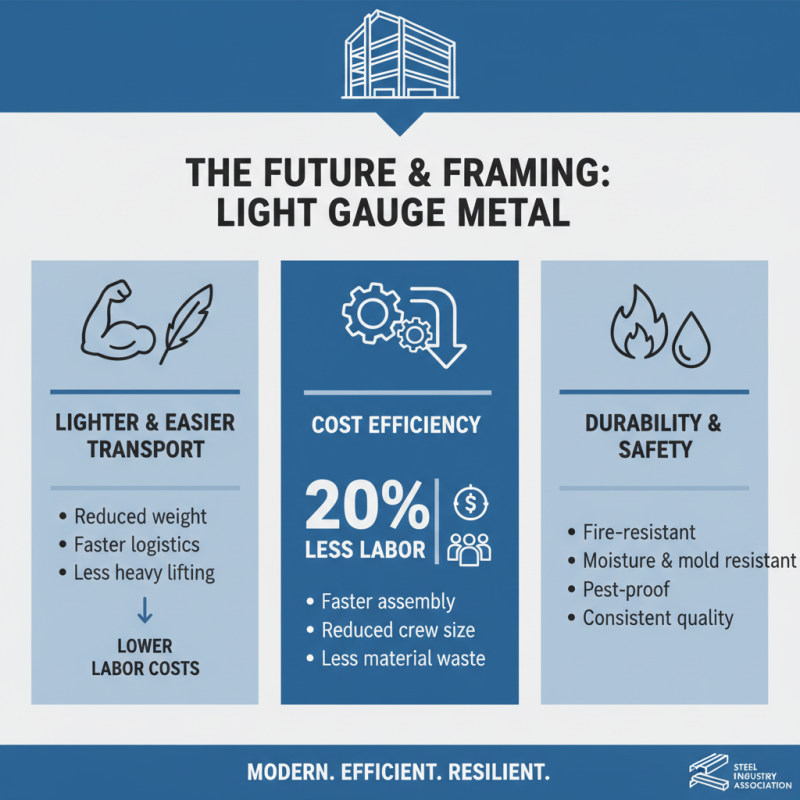

Light gauge metal framing is becoming more popular in construction. When compared to traditional wood framing, it offers several advantages. For instance, it is lighter and easier to transport. This can reduce overall labor costs on job sites. According to a report from the Steel Framing Industry Association, projects utilizing metal framing can often use up to 20% less labor than those with wood.

While light gauge metal framing boasts durability and resistance to pests, there are some challenges to consider. Installation can require specialized tools and training. Not all contractors have experience with metal systems, which can lead to delays. The National Association of Home Builders notes that even minor mistakes can impact structural integrity, necessitating meticulous planning.

The thermal performance of light gauge framing may not match that of traditional methods. Insulation options can vary significantly. A building's energy efficiency relies heavily on these factors. A study from the Department of Energy suggests that addressing insulation correctly is key for both frame types. While metal framing presents unique benefits, careful consideration of its limitations is essential for successful implementation.

Related Posts

-

How to Install Light Gauge Metal Framing for Your Construction Project?

-

How to Choose the Right Metal Framing Systems for Your Construction Project

-

2026 Top Trends in Metal Framing Systems for Modern Construction?

-

How to Use Light Gauge Steel Framing for Your Next Construction Project?

-

How to Choose the Best Composite Deck Joists for Long-lasting Durability and Performance

-

Why Cold Formed Metal Framing is the Future of Sustainable Construction Solutions