What is Light Gauge Steel Framing and Its Benefits for Modern Construction

In recent years, the construction industry has witnessed a significant shift towards innovative building materials and methods, among which light gauge steel framing stands out for its numerous advantages. As construction expert Dr. Emily Carter, a renowned advocate for modern building solutions, aptly puts it, "Light gauge steel framing not only enhances structural integrity but also offers unparalleled design flexibility." This innovative approach utilizes steel that is thinner and lighter than traditional steel structures, making it an ideal choice for various applications, from residential homes to commercial buildings.

Light gauge steel framing provides a sustainable alternative to conventional wood framing, addressing concerns about deforestation and resource depletion. Its durability and resistance to pests, rot, and fire further contribute to its appeal in today's construction landscape. Additionally, this method facilitates quicker construction times and reduced labor costs, offering a practical solution that meets the demands of modern architecture. As the industry continues to evolve, embracing light gauge steel framing signifies a commitment to efficiency, sustainability, and enhanced building performance, paving the way for the future of construction.

Definition of Light Gauge Steel Framing and Its Composition

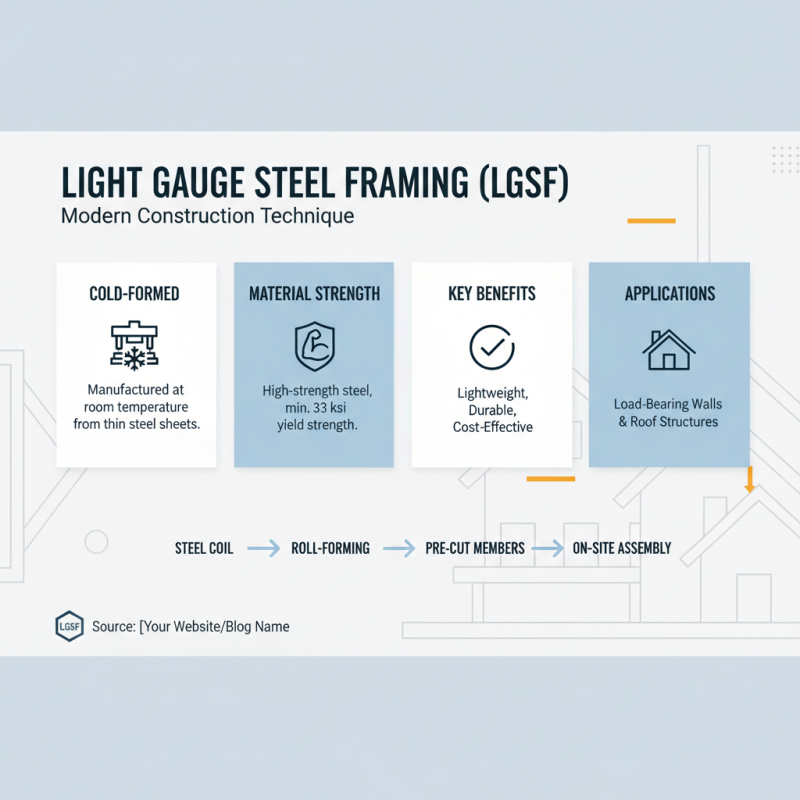

Light Gauge Steel Framing (LGSF) is a modern construction technique that utilizes thin sheets of steel formed into structural members. These members are typically cold-formed, which means they are manufactured at room temperature. The composition of light gauge steel generally includes high-strength steel, often with a minimum yield strength of 33 ksi, which provides the necessary structural integrity while keeping the material lightweight. This characteristic allows for load-bearing wall systems and roof structures that are durable and cost-effective.

The framing is composed of various components, including studs, tracks, and braces, all of which are engineered for specific applications within a building's framework. The studs act as vertical supports, while the tracks serve as horizontal rails that hold the studs in place. Moreover, bracing elements are incorporated to enhance stability and resist lateral forces. The precision of LGSF systems ensures that these components can be prefabricated with high accuracy, reducing waste and construction time. This assembly of materials not only supports various architectural designs but also contributes to energy efficiency and sustainability in modern construction practices.

Historical Development and Evolution of Light Gauge Steel Framing

The development of light gauge steel framing (LGSF) can be traced back to the late 19th and early 20th centuries, coinciding with the industrial revolution's advancements in metallurgy and engineering. Initially, steel was mostly used in heavy construction, but as techniques improved, lighter and thinner steel sections emerged, enabling the creation of more versatile building systems. By the 1950s, the introduction of cold-formed steel processes marked a significant turning point, allowing for the mass production of standardized steel shapes that could be efficiently used in residential and commercial construction.

Over the decades, the continuous refinement of light gauge steel technology has led to its increased popularity in modern construction. The introduction of advanced coatings and corrosion-resistant materials enhanced the durability of LGSF, making it a viable alternative to traditional wood framing. Furthermore, the flexibility and ease of assembly associated with light gauge steel have made it an attractive option for architects and builders who require design adaptability and rapid construction timelines. As the construction industry embraces sustainable practices, LGSF's recyclability and reduced waste generation further underscore its relevance in contemporary building practices.

Key Advantages of Light Gauge Steel Framing in Modern Construction

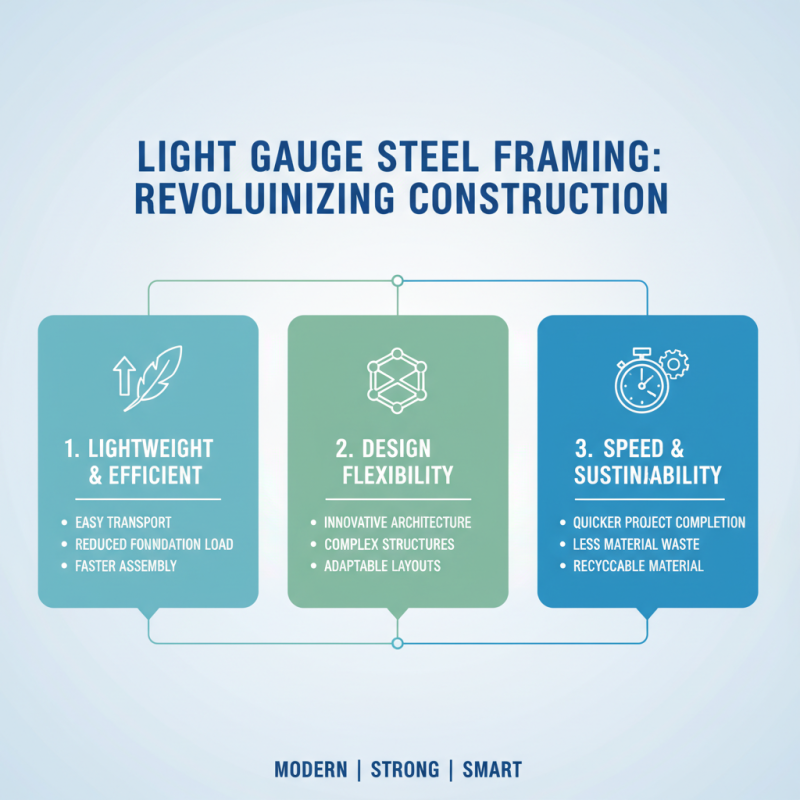

Light gauge steel framing has emerged as a revolutionary approach in modern construction, providing numerous advantages that cater to the needs of contemporary building projects. One of the most significant benefits is its lightweight nature, which simplifies transportation and reduces structural load on foundations. This ease of handling not only speeds up the construction process but also allows for more flexible design options, enabling architects and builders to create innovative and intricate structures without the constraints typically associated with heavier materials.

Another key advantage of light gauge steel framing is its durability and resistance to environmental factors. Unlike traditional materials such as wood, steel does not warp, crack, or succumb to pests, ensuring that buildings maintain their structural integrity over time. Additionally, steel is non-combustible, enhancing the fire safety of the construction. This resilience makes light gauge steel an ideal choice for energy-efficient designs, as it can better support insulation materials and contribute to overall sustainability. As modern construction continues to evolve, the preference for light gauge steel framing is likely to grow, driven by its performance and adaptability to various architectural styles.

Comparison of Light Gauge Steel Framing to Traditional Building Materials

Light Gauge Steel Framing (LGSF) has gained traction in modern construction due to its numerous advantages over traditional building materials such as wood and concrete. One significant difference lies in the material's strength-to-weight ratio. Light gauge steel offers superior structural support while being lighter than conventional materials, making it easier to handle and reducing transportation costs. Furthermore, LGSF is resistant to various environmental factors, including pests, rot, and fire, leading to enhanced durability and lower maintenance expenses over the lifespan of a building.

In terms of construction efficiency, light gauge steel framing can lead to faster project completion times. Its prefabrication process allows for quicker assembly on-site, thereby reducing labor costs and minimizing delays caused by weather conditions that can impact traditional building methods. In contrast, wood is subject to shrinkage, swelling, and warping, which can complicate the construction process. Additionally, steel's recyclability contributes to sustainability goals, making it an environmentally friendly alternative to timber, which often involves deforestation and habitat disruption. Overall, the comparison highlights LGSF as a competitive choice for modern construction projects, balancing performance, sustainability, and cost-effectiveness.

Applications and Use Cases of Light Gauge Steel Framing in Construction

Light gauge steel framing is increasingly favored in modern construction due to its versatility and durability. One of the primary applications of light gauge steel framing is in residential construction, where it serves as an excellent alternative to traditional wood framing. With its lightweight nature and high strength, steel framing can support larger structures while minimizing the material needed, ultimately reducing costs and construction time. Additionally, the non-combustible properties of steel make it an ideal choice for enhancing fire safety in homes, providing peace of mind for homeowners.

Beyond residential applications, light gauge steel framing is also utilized in commercial buildings, including office complexes and retail spaces. Its adaptability allows for easy modifications and extensions, making it suitable for evolving business needs. Furthermore, the precision manufacturing of steel components ensures a higher level of consistency and quality in construction. This accuracy results in reduced waste and improved sustainability, aligning with the growing demand for environmentally friendly building practices. Overall, light gauge steel framing is a compelling choice for constructors looking to balance efficiency, safety, and sustainability in their projects.

What is Light Gauge Steel Framing and Its Benefits for Modern Construction

| Dimension | Description | Benefits | Common Applications |

|---|---|---|---|

| Material | Thin sheets of galvanized steel | Corrosion resistance | Residential buildings |

| Weight | Lightweight construction material | Easier to handle and transport | Commercial buildings |

| Sustainability | Recyclable material | Lower environmental impact | Modular construction |

| Speed of Construction | Pre-engineered components | Faster assembly on site | Industrial buildings |

| Design Flexibility | Versatile framing options | Allows for innovative designs | Mixed-use developments |

Related Posts

-

How to Choose Cold Formed Metal Framing for Your Construction Project

-

What is Steel Framing and How It Transforms Construction Efficiency and Durability

-

How to Choose the Right Metal Framing Systems for Your Construction Project

-

2025 How to Choose the Right Exterior Sheathing for Your Home

-

2025 Top Trends in Light Gauge Metal Framing: Key Benefits and Innovations

-

2025 Top Composite Deck Trends and Ideas for Your Outdoor Space