How to Use Light Gauge Steel Framing for Your Next Construction Project?

In construction, the choice of materials greatly influences the outcome. Light gauge steel framing stands out as a modern solution. This technique offers strength and durability, making it ideal for various projects.

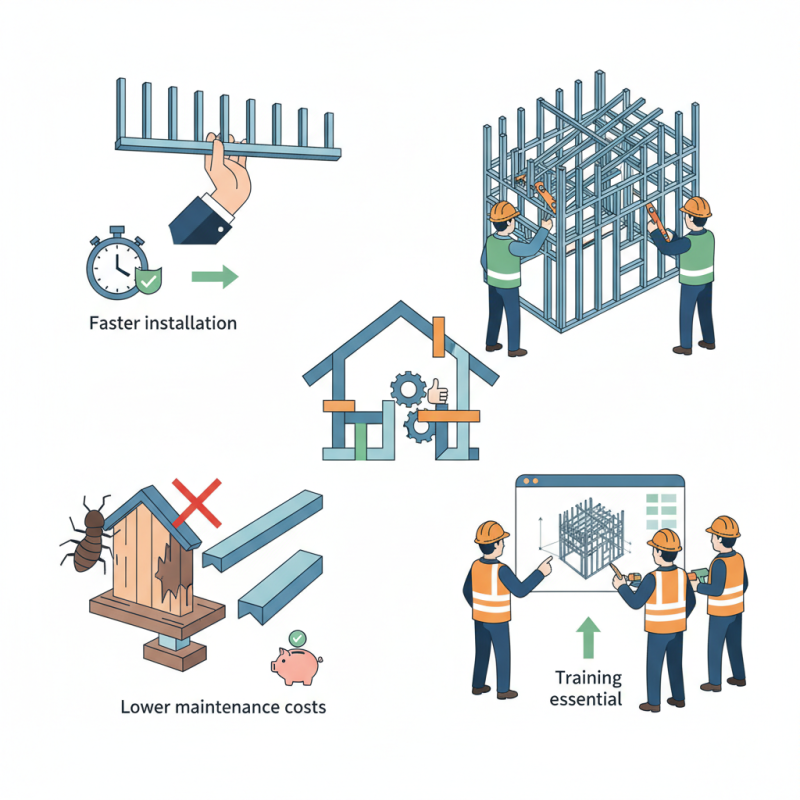

Many builders appreciate the lightweight nature of steel. It allows for easier handling and faster installation. However, there are challenges to consider. Misalignment during installation can lead to structural issues. Attention to detail is crucial in these scenarios.

Moreover, light gauge steel framing is resistant to pests and decay. This can lower maintenance costs over time. Yet, not all workers are familiar with this method. Training is essential to maximize its benefits. Overall, light gauge steel framing can transform your construction project when applied correctly.

Understanding Light Gauge Steel Framing: Basics and Benefits

Light gauge steel framing is an innovative construction method gaining popularity. It involves thin steel sections that create a strong, durable framework. This approach offers several benefits for builders and homeowners alike.

One key advantage is its resistance to many environmental factors. Steel is non-combustible, meaning it won’t catch fire easily. It also resists pests like termites. These qualities contribute to the longevity of structures. However, the initial cost can be higher than traditional lumber. Builders must weigh this against the potential for fewer repairs down the line.

Construction efficiency is another notable benefit. Light gauge steel is lighter than wood but equally strong. This makes transportation easier and reduces labor costs. However, not all builders are familiar with this technique. Training may be necessary, which can slow project timelines. Understanding these fundamentals can help in planning your next construction venture.

Light Gauge Steel Framing Benefits in Construction Projects

Selecting the Right Materials for Light Gauge Steel Framing Projects

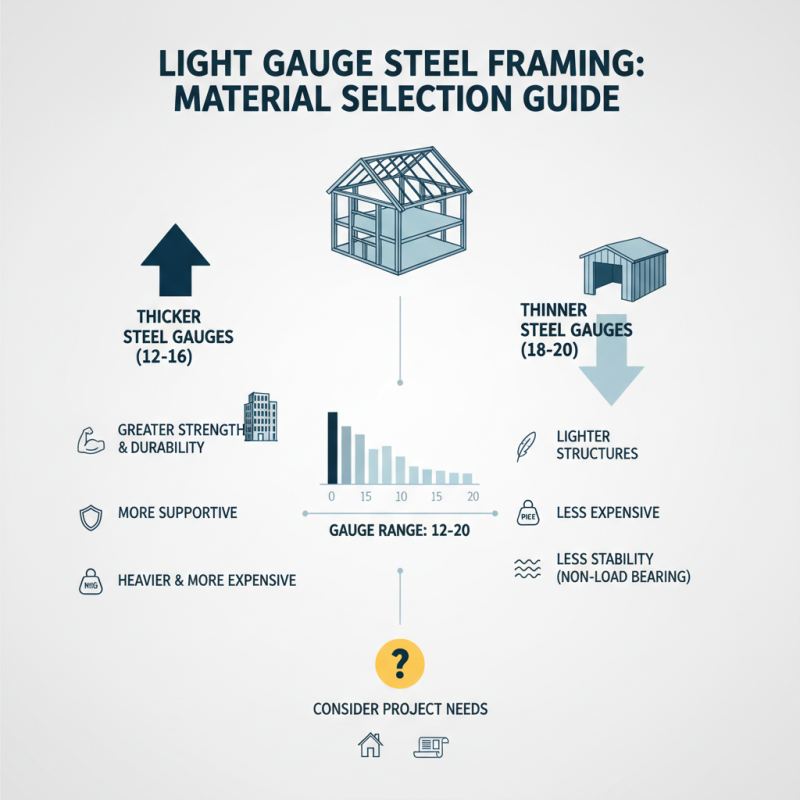

When starting a light gauge steel framing project, selecting the right materials is crucial. Consider your project’s specific needs. The thickness of the steel will impact its strength and durability. Typically, steel gauges range from 12 to 20. Thicker gauges offer greater support but can be heavier and more expensive. Thin gauges work for lighter structures but may lack stability.

Adhesives and fasteners are also important. Using the wrong type can weaken your structure. Therefore, choose high-quality screws and connectors designed for steel. Pay attention to the environment too; moisture can lead to corrosion. Incorporating protective coatings may help prolong the life of the framing.

Additionally, the layout of your design should not be overlooked. A well-thought-out plan reduces material waste. Many projects run into avoidable issues if not properly mapped. While light gauge steel can be cost-effective, any miscalculation can lead to added expenses. Reflecting on your choices at every stage will enhance the project’s overall quality and performance.

Step-by-Step Guide to Designing Your Light Gauge Steel Frame Structure

Light gauge steel framing is becoming popular in construction. Its lightweight nature allows for quicker transport and assembly. Studies show that structures using light gauge steel can reduce material waste by up to 30%. This efficiency can save money and time, making it an attractive option for builders.

Designing your light gauge steel frame structure involves careful planning. Start with a clear architectural design. Consider factors like load-bearing requirements and local building codes. It's crucial to detail all dimensions accurately. A small mistake can lead to significant issues later. Ensure that your designs can withstand environmental factors such as wind, rain, and snow.

Tips: Always double-check your measurements to avoid costly errors. Use software to assist with structural calculations. Collaborate with experienced professionals early in the design process. This might feel challenging, but it pays off in the long run. Keep in mind that while light gauge steel offers many benefits, it requires proper handling to avoid issues like corrosion. Addressing these details can make a big difference in the success of your project.

Best Practices for Installation of Light Gauge Steel Framing

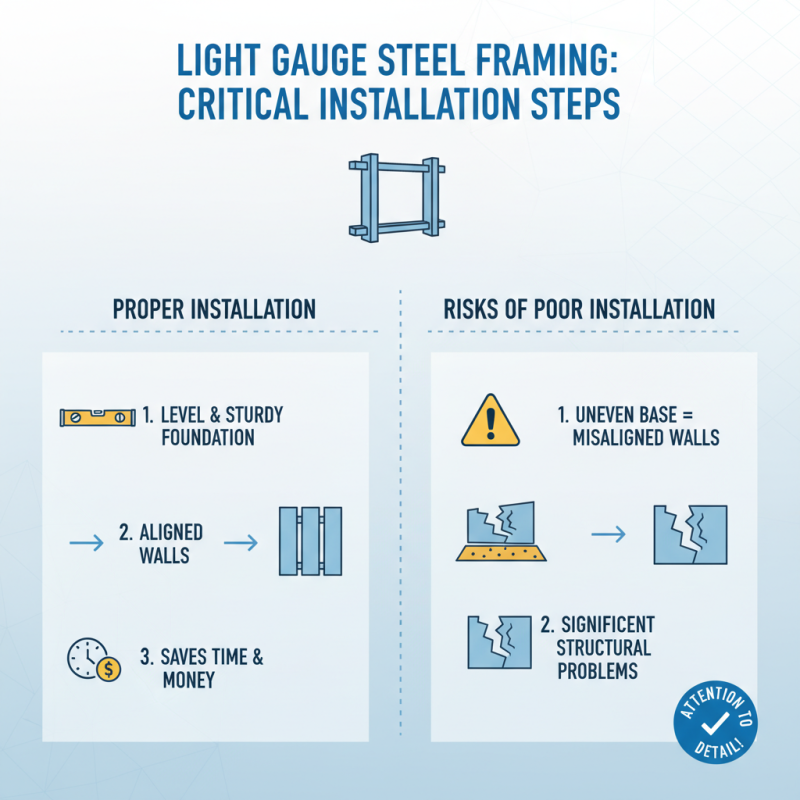

Using light gauge steel framing can be effective for many construction projects. However, installation must be done correctly to avoid future issues. Start by ensuring the foundation is level and sturdy. If the base is uneven, the walls will not align properly. This can lead to significant structural problems later. Attention to detail here saves time and money.

When assembling the framing, follow the manufacturer's guidelines closely. Misalignment is a common issue that can weaken the frame. It's essential to measure twice and cut once. Use screws rather than nails for better strength. Remember, excessive reliance on power tools can lead to mistakes. Hand tools allow for better control in tight spots.

Finally, don't rush the process. Installation errors can be costly. Regular checks during the build help catch mistakes early. While light gauge steel is durable, improper installation can compromise its advantages. Reflecting on these practices can lead to a more successful project. Taking the time to evaluate your work is beneficial.

Final Inspections and Finishing Touches for Steel Framed Projects

Final inspections are crucial for any steel-framed project. They ensure compliance with safety standards and building codes. According to recent industry research, buildings using light gauge steel framing exhibit fewer structural failures. Completing thorough inspections can highlight areas needing improvement.

During the finishing touches phase, pay attention to proper insulation and moisture barriers. This step helps prevent future issues, such as mold growth or energy loss. A report from the Steel Framing Alliance emphasizes that effective insulation improves energy efficiency, saving homeowners money in the long run.

Tip: Always utilize moisture-resistant materials for the finishing touches. This approach enhances durability and overall project quality. Inspect every detail, from the framing to the final paint. It's easy to overlook small issues. Neglecting these can lead to costly repairs later. Be diligent; don't rush through this essential stage. Your effort now can result in a sturdier structure.

Related Posts

-

Why Choose Light Steel Framing for Your Next Construction Project

-

How to Choose the Right Metal Framing Systems for Your Construction Project

-

2026 Top Composite Deck Trends You Need to Know?

-

2025 Top 10 Innovative Steel Metal Products Redefining Industry Standards

-

How to Choose Cold Formed Metal Framing for Your Construction Project

-

10 Essential Tips for Using Precast Concrete in Your Next Project