How to Use Steel Framing for Your Construction Projects?

Steel framing has gained popularity in modern construction. This method offers a lightweight yet durable alternative to traditional wood framing. Builders appreciate its resistance to pests, moisture, and fire. With steel, projects can achieve greater structural integrity. It supports larger spans, allowing for open floor plans.

Implementing steel framing requires careful planning. Even skilled workers can face challenges during the installation process. Precise measurements are crucial. Miscalculations can lead to costly errors. Additionally, the use of steel demands proper tools and safety measures. Not all teams may be equipped for this material.

Incorporating steel framing into your construction projects can enhance longevity. However, it may also require adjustments in design thinking. Embracing new techniques often brings its own set of hurdles. Construction is a learning journey, enriching your toolkit with every project. Steel framing, while beneficial, invites ongoing reflection on best practices and efficiencies.

Understanding Steel Framing: Basics and Benefits

Steel framing has become a popular choice in construction. Understanding its basics and benefits can help you make better decisions for your projects. Steel is strong and durable. It resists fire, pests, and decay. This makes it a smart alternative to wood. Steel framing provides structural integrity, ensuring safety over time.

When planning your projects, consider these tips. Always check local codes. Regulations can vary widely. Using steel might require different methods than traditional framing. Also, think about insulation needs. Steel can transfer heat. Proper insulation is crucial to energy efficiency.

Another point to reflect on is your team’s experience. Not everyone is familiar with steel framing. Training can be necessary. It might slow down initial progress. But ultimately, investing in skills pays off. Your projects will benefit from knowledgeable workers. Remember, the initial challenges can lead to long-term advantages.

How to Use Steel Framing for Your Construction Projects?

| Dimension | Description | Benefits |

|---|---|---|

| Weight | Lightweight compared to wood or concrete | Easier handling and reduced labor costs |

| Durability | Resistant to rot, termites, and other pests | Longer lifespan and lower maintenance costs |

| Fire Resistance | Non-combustible material | Improved safety and compliance with building codes |

| Flexibility | Easily adaptable to various designs and layouts | Allows for creative architectural solutions |

| Sustainability | Made from recyclable materials | Supports green building practices |

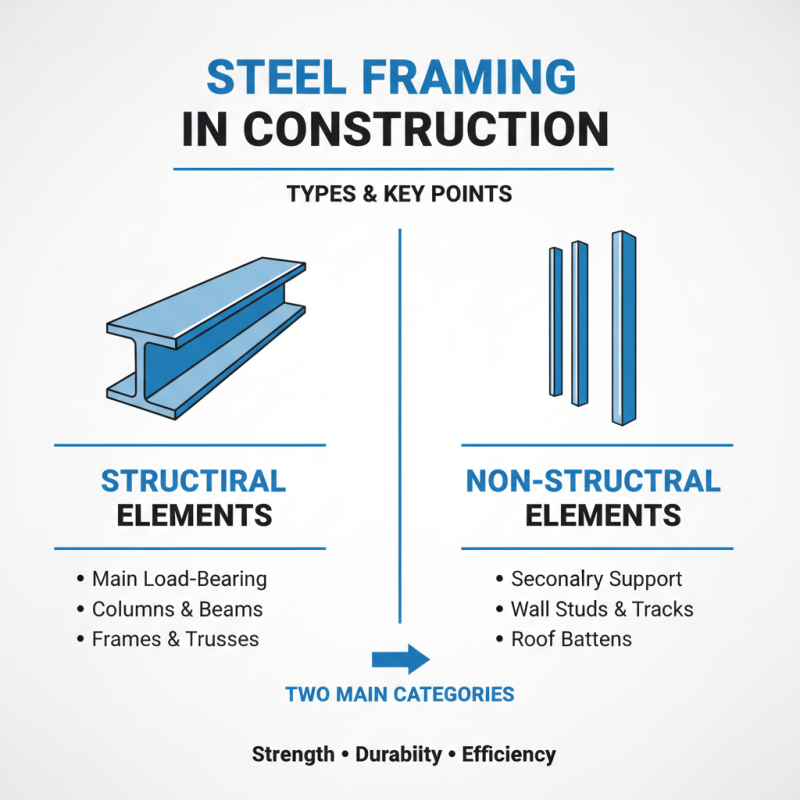

Types of Steel Framing: Structural and Non-Structural Elements

Steel framing is becoming popular in construction projects. Understanding the types is crucial. Two main categories exist: structural and non-structural elements.

Structural elements are essential for load-bearing. They include beams, columns, and trusses. These components provide stability. They are key in skyscrapers and large buildings. Without them, structures may collapse under pressure. Choosing the right size and type is vital. Consider local building codes and environmental factors.

Non-structural elements add functionality. These include partitions, cladding, and ceilings. They enhance aesthetics but do not support loads. It's easy to overlook their importance. They can significantly impact energy efficiency. As a tip, always consult with a designer when selecting materials. Small mistakes can lead to bigger issues. Keep an eye on costs as well.

When planning your project, think about both elements. Balance structural integrity with design appeal. Strive for efficiency in material usage. Reflect on what works best for your needs. The right combination can lead to a successful build.

Planning and Designing with Steel Framing Techniques

When planning with steel framing, it’s essential to consider the project’s specific needs. Steel framing offers strength and durability. According to the American Iron and Steel Institute, steel is up to 30% lighter than wood while being much stronger. This balance of weight and strength can significantly impact design choices.

Designing layouts correctly is crucial. The spacing of steel studs affects both material costs and structural integrity. A common mistake is assuming that standard spacing will work in all scenarios. In a report by the Steel Framing Alliance, projects with improperly spaced studs saw increased rework costs of up to 15%. Careful calculations can prevent these issues and save money.

Another detail to ponder is the environmental impact. Steel can be recycled, reducing waste. However, sourcing steel can leave a substantial carbon footprint. Designers must weigh these factors. Are the benefits of steel worth its environmental costs? The answer varies between projects. Each decision should be informed and deliberate. Inadequate analysis may lead to struggles later in the construction process.

Steel Framing Usage in Construction Projects

Steps to Install Steel Framing in Construction Projects

Installing steel framing can be an effective choice for construction projects. The process requires careful planning and attention to detail. Start by measuring the space where the steel frame will be installed. Accurate measurements are essential. They help ensure that the frame fits properly, reducing the need for adjustments later.

Once measurements are taken, gather necessary tools and materials. Tools may include a level, a drill, and protective gear. Steel studs and tracks should be ready to use. Begin by marking the layout on the floor and walls. Accurate markings guide the installation process. Remember to check the level frequently. This step is crucial. A frame that isn’t straight can lead to complications down the line.

Assembling the frame involves connecting the tracks and studs. It can feel repetitive and tiring. Pay attention to the connections to ensure they are secure. Sometimes, a stud may bend or not align perfectly. It’s important to assess these issues immediately. Small mistakes can lead to larger problems. After the frame is assembled, inspect for stability. This step is often overlooked but crucial for long-term durability. Reflect on any discrepancies and adjust as necessary.

Common Challenges and Solutions in Steel Framing Applications

Steel framing offers durability and strength in construction. However, it comes with its own set of challenges. One common issue is rust and corrosion, especially in certain climates. Regular maintenance and using proper coatings can mitigate this risk. Ensuring adequate drainage and ventilation within the framing system also helps.

Another challenge is the difficulty of modifications. Steel is not as forgiving as wood. Once cut, it can weaken the frame structure. This requires thoughtful planning before installation. Use precise measurements and proper tools to minimize errors. The weight of steel can strain transport and installation. Ensure your team is trained to handle these issues safely.

Thermal conductivity is another concern. Steel can transfer heat or cold more quickly than other materials. This can lead to energy inefficiencies in your building. Solutions include incorporating thermal breaks and suitable insulation. Overall, paying attention to these challenges can lead to better outcomes in your building projects.

Related Posts

-

2026 Top Trends in Gauge Steel Applications and Innovations?

-

How to Choose the Right Metal Framing Systems for Your Construction Project

-

Top 10 Benefits of Precast Concrete for Modern Construction Projects

-

Best Deck System Solutions for Enhanced Outdoor Living?

-

Why Choose Light Steel Framing for Your Next Construction Project

-

2026 Top Composite Deck Trends You Need to Know?